“Maintain the flow: Control conductivity in water.”

Table of Contents

Methods for Monitoring and Adjusting Conductivity Levels in Water

Water conductivity is a crucial parameter that can indicate the presence of dissolved ions in water. High conductivity levels can be a sign of contamination, while low levels can indicate a lack of essential minerals. Monitoring and controlling conductivity in water is essential for ensuring water quality and safety. In this article, we will discuss methods for monitoring and adjusting conductivity levels in water.

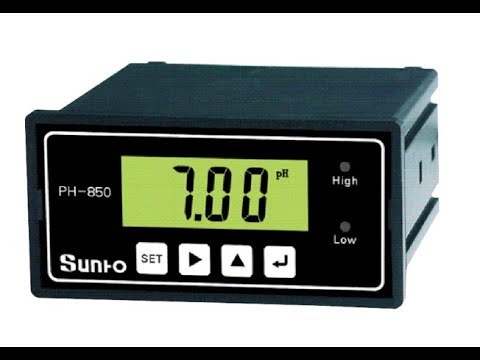

One of the most common methods for monitoring conductivity in water is using a conductivity meter. These devices measure the electrical conductivity of water, which is directly related to the concentration of ions present. Conductivity meters are easy to use and provide real-time data on water quality. Regular monitoring with a conductivity meter can help identify changes in water quality and potential contamination.

In addition to using a conductivity meter, water treatment plants often use online monitoring systems to continuously monitor conductivity levels in water. These systems can provide real-time data and alerts for any sudden changes in conductivity. Online monitoring systems are essential for ensuring water quality and safety in large-scale water treatment facilities.

Adjusting conductivity levels in water can be done through various methods. One common method is using ion exchange resins to remove ions from water. Ion exchange resins work by exchanging ions in water with ions on the resin, effectively reducing conductivity levels. This method is commonly used in water softening systems to remove calcium and magnesium ions.

Another method for adjusting conductivity levels in water is through reverse osmosis. Reverse osmosis is a water purification process that uses a semi-permeable membrane to remove ions, molecules, and larger particles from water. This process can effectively reduce conductivity levels in water and improve water quality.

Chemical treatment is another method for adjusting conductivity levels in water. Chemicals such as coagulants and flocculants can be added to water to remove ions and improve water clarity. Chemical treatment is often used in conjunction with other methods to achieve the desired conductivity levels in water.

It is essential to regularly monitor and adjust conductivity levels in water to ensure water quality and safety. High conductivity levels can indicate contamination, while low levels can affect water taste and quality. By using conductivity meters, online monitoring systems, ion exchange resins, reverse osmosis, and chemical treatment, water treatment facilities can effectively control conductivity levels in water.

In conclusion, monitoring and adjusting conductivity levels in water is essential for ensuring water quality and safety. By using a combination of methods such as conductivity meters, online monitoring systems, ion exchange resins, reverse osmosis, and chemical treatment, water treatment facilities can effectively control conductivity levels in water. Regular monitoring and adjustments are necessary to maintain water quality standards and protect public health.

Importance of Proper Water Treatment to Control Conductivity Levels

Water is an essential resource that we rely on for various purposes, from drinking and cooking to industrial processes and agriculture. However, the quality of water can vary significantly depending on its source and treatment. One important aspect of water quality that needs to be carefully monitored and controlled is conductivity.

| Model | pH/ORP-8500A pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP:(-1999~+1999)mV; Temp.:(0.0~100.0)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | NTC10K Temperature compensation |

| Medium Temp. | (0~80)°C |

| Analog output | Double channels isolated; transportable(4~20)mA, instruments/ transmitter mode |

| Control Output | Triple channels semiconductor photoelectric switch, load current: AC/DC 30V, 50mA(max) |

| Communication port | RS485,Modbus RTU protocol |

| Working Environment | Temp.(0~80)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx94mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

Conductivity is a measure of how well water can conduct electricity, which is influenced by the presence of dissolved ions such as salts and minerals. High conductivity levels in water can indicate the presence of contaminants or impurities that may be harmful to human health or the environment. Therefore, it is crucial to control conductivity levels in water to ensure its safety and suitability for its intended use.

Proper water treatment is essential to control conductivity levels and maintain water quality. One common method used to reduce conductivity in water is through the process of deionization. Deionization involves removing ions from water by passing it through ion exchange resins that attract and bind to the ions, effectively reducing conductivity.

Another method to control conductivity in water is through reverse osmosis. Reverse osmosis is a filtration process that uses a semi-permeable membrane to remove ions, molecules, and larger particles from water, resulting in a significant reduction in conductivity. This method is particularly effective in removing dissolved salts and minerals that contribute to high conductivity levels.

In addition to deionization and reverse osmosis, other water treatment processes such as distillation, carbon filtration, and UV disinfection can also help control conductivity levels by removing impurities and contaminants from water. It is essential to choose the appropriate water treatment method based on the specific characteristics of the water source and the desired water quality standards.

Regular monitoring and testing of water conductivity levels are crucial to ensure that the chosen water treatment method is effective in controlling conductivity. Conductivity meters are commonly used to measure the conductivity of water and provide real-time data on its quality. By regularly monitoring conductivity levels, water treatment operators can adjust treatment processes as needed to maintain optimal water quality.

| ROS-360 Water Treatment RO Programmer Controller | ||

| Model | ROS-360 Single Stage | ROS-360 Double Stage |

| Measuring range | Source water0~2000uS/cm | Source water0~2000uS/cm |

| First level effluent 0~1000uS/cm | First level effluent 0~1000uS/cm | |

| secondary effluent 0~100uS/cm | secondary effluent 0~100uS/cm | |

| Pressure sensor(optional) | Membrane pre/post pressure | Primary/ secondary membrane front/rear pressure |

| Flow Sensor(optional) | 2 channels (Inlet/outlet flow rate) | 3 channels (source water, primary flow,secondary flow) |

| IO input | 1.Raw water low pressure | 1.Raw water low pressure |

| 2.Primary booster pump inlet low pressure | 2.Primary booster pump inlet low pressure | |

| 3.Primary booster pump outlet high pressure | 3.Primary booster pump outlet high pressure | |

| 4.High liquid level of Level 1 tank | 4.High liquid level of Level 1 tank | |

| 5.Low liquid level of Level 1 tank | 5.Low liquid level of Level 1 tank | |

| 6.Preprocessing signal | 6.2nd booster pump outlet high pressure | |

| 7.High liquid level of Level 2 tank | ||

| 8.Preprocessing signal | ||

| Relay output (passive) | 1.Water inlet valve | 1.Water inlet valve |

| 2.Source water pump | 2.Source water pump | |

| 3.Booster pump | 3.Primary booster pump | |

| 4.Flush valve | 4.Primary flush valve | |

| 5.Water over standard discharge valve | 5.Primary water over standard discharge valve | |

| 6.Alarm output node | 6.Secondary booster pump | |

| 7.Manual standby pump | 7.Secondary flush valve | |

| 8.Secondary water over standard discharge valve | ||

| 9.Alarm output node | ||

| 10.Manual standby pump | ||

| The main function | 1.Correction of electrode constant | 1.Correction of electrode constant |

| 2.TDS alarm setting | 2.TDS alarm setting | |

| 3.All working mode time can be set | 3.All working mode time can be set | |

| 4.High and low pressure flushing mode setting | 4.High and low pressure flushing mode setting | |

| 5.Manual/automatic can be chosen when boot up | 5.Manual/automatic can be chosen when boot up | |

| 6.Manual debugging mode | 6.Manual debugging mode | |

| 7.Spare parts time management | 7.Spare parts time management | |

| Expansion interface | 1.Reserved relay output | 1.Reserved relay output |

| 2.RS485 communication | 2.RS485 communication | |

| Power supply | DC24V±10% | DC24V±10% |

| Relative humidity | ≦85% | ≤85% |

| Environment temperature | 0~50℃ | 0~50℃ |

| Touch screen size | Touch screen size: 7 inches 203*149*48mm (Hx Wx D) | Touch screen size: 7 inches 203*149*48mm (Hx Wx D) |

| Hole Size | 190x136mm(HxW) | 190x136mm(HxW) |

| Installation | Embedded | Embedded |

Controlling conductivity in water is not only important for ensuring its safety and suitability for various uses but also for protecting equipment and infrastructure from corrosion and scale buildup. High conductivity levels can lead to accelerated corrosion of metal pipes and equipment, as well as the formation of scale deposits that can clog pipes and reduce the efficiency of water systems.

In conclusion, proper water treatment is essential to control conductivity levels and maintain water quality. By using appropriate treatment methods such as deionization, reverse osmosis, and other filtration processes, water treatment operators can effectively reduce conductivity and ensure the safety and suitability of water for its intended use. Regular monitoring and testing of water conductivity levels are crucial to ensure that treatment processes are effective in controlling conductivity and maintaining optimal water quality. By taking proactive measures to control conductivity in water, we can protect human health, the environment, and water infrastructure from the harmful effects of high conductivity levels.