“Measure the flow of electricity with precision and accuracy.”

Table of Contents

Benefits of Using a conductivity meter in water Quality Testing

Conductivity meters are essential tools in water quality testing, providing valuable information about the purity and safety of water. These devices measure the ability of water to conduct an electrical current, which is directly related to the concentration of ions present in the water. Conductivity meters are widely used in various industries, including environmental monitoring, agriculture, and food and beverage production, to ensure that water meets regulatory standards and is safe for consumption.

One of the key benefits of using a conductivity meter is its ability to quickly and accurately assess the overall quality of water. By measuring the conductivity of water, users can determine the presence of dissolved solids, such as salts, minerals, and other contaminants, which can affect the taste, odor, and safety of water. Conductivity meters provide real-time data, allowing users to make informed decisions about water treatment and purification processes.

In addition to assessing water quality, conductivity meters are also used to monitor the performance of water treatment systems. By regularly measuring the conductivity of water before and after treatment, operators can ensure that the treatment process is effectively removing contaminants and producing clean, safe water. Conductivity meters can also help identify potential issues with treatment equipment, such as fouled membranes or malfunctioning filters, before they lead to water quality problems.

Conductivity meters are also valuable tools for monitoring water in agricultural settings. Farmers use conductivity meters to assess the quality of irrigation water, which can affect crop growth and yield. By measuring the conductivity of water, farmers can determine the salinity levels and nutrient content of the water, allowing them to make adjustments to their irrigation practices to optimize crop production. Conductivity meters can also help farmers identify potential sources of contamination in water sources, such as runoff from fertilizers or pesticides, which can impact the health of crops and the environment.

In the food and beverage industry, conductivity meters are used to ensure the quality and safety of products. By measuring the conductivity of water used in production processes, manufacturers can maintain consistent product quality and meet regulatory standards for purity and safety. Conductivity meters are also used to monitor the quality of water used in cleaning and sanitation processes, helping to prevent contamination and ensure the cleanliness of equipment and facilities.

| Model | pH/ORP-1800 pH/orp meter |

| Range | 0-14 pH; -1600 – +1600mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Manual/Automatic temperature compensation; No Comp. |

| Oper. Temp. | Normal 0~50℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | 128*64 LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×100mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

Overall, conductivity meters play a crucial role in ensuring the quality and safety of water in various industries. These devices provide valuable data that can help users make informed decisions about water treatment, irrigation practices, and product quality. By measuring the conductivity of water, users can identify potential issues, monitor performance, and maintain regulatory compliance. Conductivity meters are essential tools for anyone involved in water quality testing and monitoring, providing accurate and reliable data that is essential for maintaining the health and safety of water sources.

How Conductivity Meters are Essential in Monitoring Industrial Processes

Conductivity meters are essential tools in monitoring industrial processes. These devices measure the ability of a solution to conduct an electric current, providing valuable information about the concentration of ions present in the solution. This information is crucial for a wide range of industries, including water treatment, pharmaceuticals, food and beverage production, and chemical manufacturing.

One of the primary uses of conductivity meters is in water treatment plants. These facilities rely on conductivity measurements to monitor the purity of water and ensure that it meets regulatory standards. By measuring the conductivity of water, operators can detect the presence of contaminants such as salts, metals, and organic compounds. This information allows them to take corrective action to remove these impurities and ensure that the water is safe for consumption.

In the pharmaceutical industry, conductivity meters play a critical role in ensuring the quality and consistency of products. Pharmaceutical manufacturers use these devices to monitor the conductivity of solutions used in drug formulations, as well as the purity of water used in production processes. By maintaining strict control over conductivity levels, manufacturers can ensure that their products meet the required specifications and are safe for use by consumers.

Similarly, conductivity meters are essential in the food and beverage industry. These devices are used to monitor the conductivity of beverages, dairy products, and other food items to ensure that they meet quality standards. By measuring the conductivity of these products, manufacturers can detect the presence of contaminants or impurities that could affect the taste, appearance, or safety of the product. This information allows them to take corrective action to maintain product quality and safety.

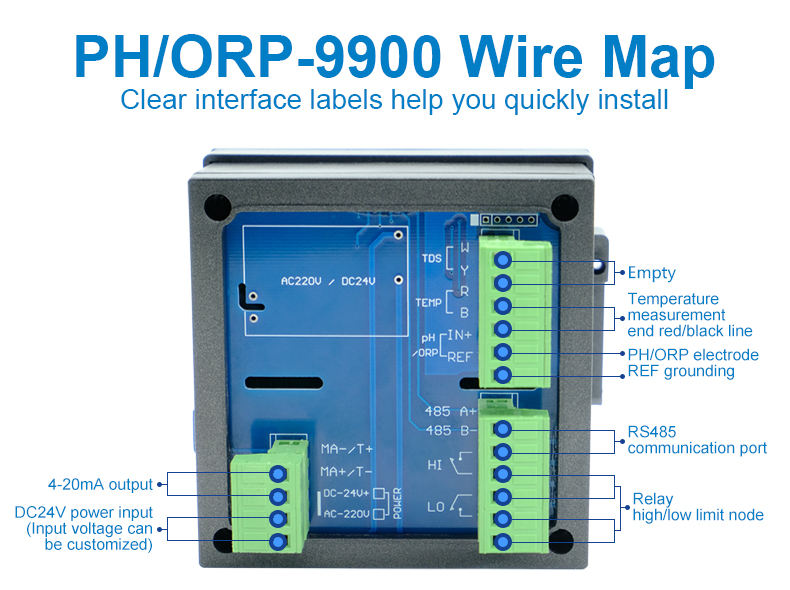

| Model | pH/ORP-8851/9900 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~60℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | Big Screen LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | DC24V/0.5A or AC85-265V±10% 50/60Hz |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×72mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In chemical manufacturing, conductivity meters are used to monitor the concentration of ions in chemical solutions. This information is crucial for controlling chemical reactions, ensuring product quality, and maintaining process efficiency. By measuring conductivity, operators can determine the concentration of acids, bases, salts, and other ions in a solution, allowing them to adjust process parameters as needed to achieve the desired outcome.

Overall, conductivity meters are essential tools in monitoring industrial processes. These devices provide valuable information about the concentration of ions in solutions, allowing operators to detect impurities, ensure product quality, and maintain process efficiency. Whether in water treatment, pharmaceuticals, food and beverage production, or chemical manufacturing, conductivity meters play a critical role in ensuring the safety, quality, and consistency of products and processes. By investing in these devices and using them effectively, industries can improve their operations, meet regulatory requirements, and deliver high-quality products to consumers.