No products were found matching your selection.

Other Related Products

-

1) Automatic softener valve Downflow and upflow type.

2) Downflow & Upflow Working Position :

a) Service->Back Wash->Downflow Brine and slow rinse->Refill ->Fast rinse->Service.

b) Service->Back Wash->Upflow Brine and slow rinse->Refill ->Fast rinse->Service.

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly.

-

Salt and water savings by using 100% capacity of the tank in service before switching to the second tank

Regenerates immediately when needed for continuous soft water

Corrosion-free fiber-reinforced polymer valve body

-

This series instruments are widely used for online pH/ORP monitoring in environment protection water treatment, pure water treatment, industrial process and so on.

-

Widely used for online measurement of acid&alkali in low concentrations and the low viscosity single-phase fluid of non-trade settlement process.

-

This series of brine valves have overcome the deficiency of the products existing in the market. It can not only protect water injection and check the air, but also can limit the extreme amount of water injection and filter the water running inside. If water injection is too fast, the liquid level inside the brine well will spill out quickly and the injection has to be shut down, which will result in the insufficiency of water inside the brine tank and have bad influence upon the outcome of recycling. This kind of brine valves depends on water pressure to work. It is reliable in working and valuable in extensive employment.

-

RF double tank floating bed plane multi-way valve, realized tow tank softening at the same time and regenerating alternate, integrated with brine jet device and brine flow meter and brine electric valve, with soft water flow meter, guarantees the water softening , the water regenerating and water filling to salt box, Complete according to the set volume.as long as the factory according to the raw water hardness set corresponding operation parameters, can always guarantee the stable operation of the equipment, guarantee the softened water and salt consumption.

-

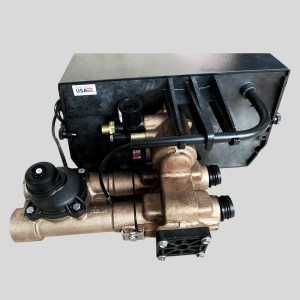

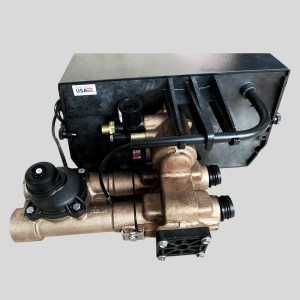

Time-tested hydraulically balanced piston, seal and spacer design to pilot service flow and regeneration

Solid, lead-free brass valve body for superior strength and durability

Backwash capacity handles tanks up to 30″ diameter

1-1/2″ top mount control valve ideal for smaller size commercial/industrial applications

Consistent brining regardless of salt levels with timed brine refills

Choice of 7 or 12 day clock, manual or meter

Continuous flow rate of 51 GPM with a backwash of 49 GPM

-

ZR type double tank floating bed control valve including ZR4-1/ZR4-1S(Side Loading), ZR10-1/ZR10-1S(Side Loading). It is equiped the inlet flow Meter and drainage flow meter, All the parameters is set by water volume, The double swap tank is for Alternating regeneration. Continuous water production, Water quality is stable , Adapted to the to high hardness water softening, such as the steam boiler and heating engineering and production process water.

-

1) Working Position : Filter->Back Wash->Fast Rinse->Filter

2) Using ceramic moving valve disk , small rotation torque

3) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

4) It could be operated with pressure directly.