Typical applications

• Widely used in thermal boiler deaerator water and large and medium-sized industrial boiler feed water;

• Operational supervision of reactor Primary circuit, secondary circuit circuits and condensate system;

• On-line analysis of dissolved oxygen in circulating water of heat exchange system;

• Deaeration control of marine fresh water system, thermal system and water cooling system;

• Measurement of dissolved oxygen and control of dosing agent in chemical deaeration process;

• Dissolved oxygen supervision of circulating water on the side of central air conditioning;

• Operation and supervision of scientific research and laboratory equipment of deaerated water;

• It is also often used for leak detection in condensate (sealed) systems.

General information

The Iot measurement terminal is the basic unit of the technology of industrial process control in the Internet + era to realize the digital material and physical connection between systems.

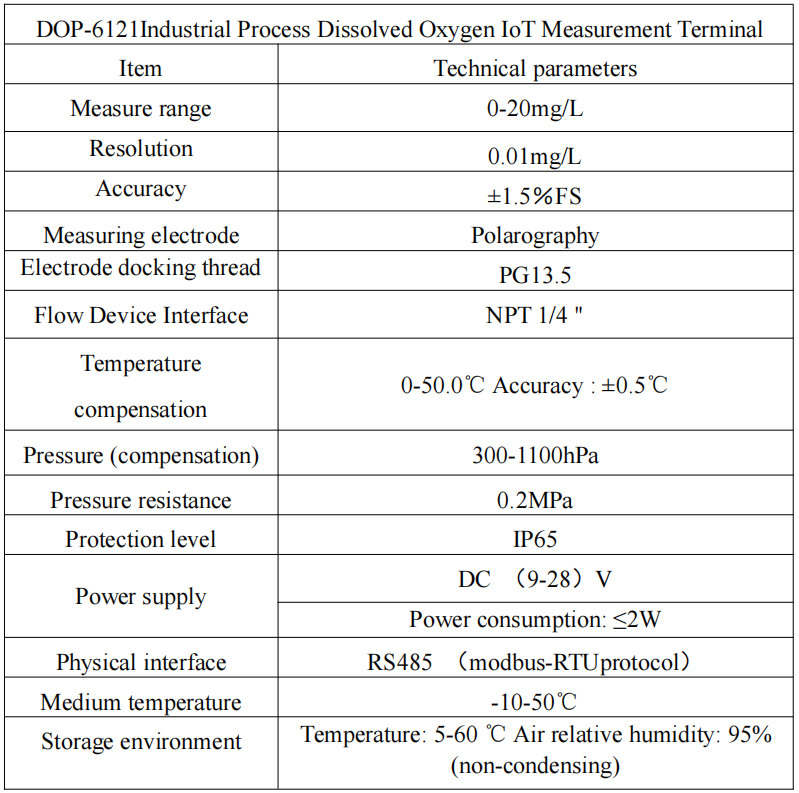

DOP-6121 is an Industrial Process Dissolved Oxygen IoT Measurement Terminal.It uses a high-performance oxygen-permeable membrane and data to respond to changes in dissolved oxygen in water in real time.

DOP-6121 directly embeds power management, data acquisition, information analysis, and communication conversion chips into the sensor, and directly integrates into the Internet system digitally. It eliminates the complex mode of conventional meters and dedicated cables, and has a simple system and wired / wireless resource modules Rich, flexible advantages.

The Industrial Process Dissolved Oxygen IoT Measurement Terminal was developed for thermal corrosion and oxygen corrosion during operation. Oxygen corrosion of thermal equipment is mainly caused by dissolved oxygen in

water.Dissolved oxygen in water is a major factor in the continued progress of acidic and alkaline corrosion.

In order to control the oxygen corrosion of thermal equipment, the dissolved oxygen content in water needs to be controlled within a certain range.The National “GB1576-85 Low-pressure Boiler Water Quality Standard” clearly stipulates:For steam boilers ≥ 2 tons / hour, hot water boilers must be deaerated as much as possible or necessary anticorrosive measures must be taken.For large-volume thermal systems, deep oxygen removal is necessary, and accurate measurement of dissolved oxygen in water in thermal systems is an important monitoring parameter for thermal systems.

Main technical features