How to Troubleshoot Common Issues with Pentair Bypass Valves

Pentair bypass valves are essential components in many water treatment systems, allowing for the diversion of water flow when needed. However, like any mechanical device, they can experience issues that may require troubleshooting. In this article, we will discuss some common problems that may arise with Pentair bypass valves and how to address them effectively.

One of the most common issues with Pentair bypass valves is leakage. This can occur for a variety of reasons, such as worn seals or gaskets, loose fittings, or debris blocking the valve’s mechanism. If you notice water leaking from the valve, the first step is to inspect the seals and gaskets for any signs of wear or damage. If necessary, replace these components to ensure a proper seal.

Another potential cause of leakage is loose fittings. Check all connections to ensure they are tight and secure. If any fittings are loose, tighten them using the appropriate tools. Additionally, make sure that there is no debris blocking the valve’s mechanism, as this can also lead to leakage. Clean the valve thoroughly to remove any obstructions that may be causing the issue.

In some cases, the bypass valve may become stuck or difficult to operate. This can be due to a buildup of mineral deposits or corrosion on the valve’s components. To address this issue, try lubricating the valve with a silicone-based lubricant to help loosen any stuck parts. If the valve is still difficult to operate, it may be necessary to disassemble it and clean the components thoroughly.

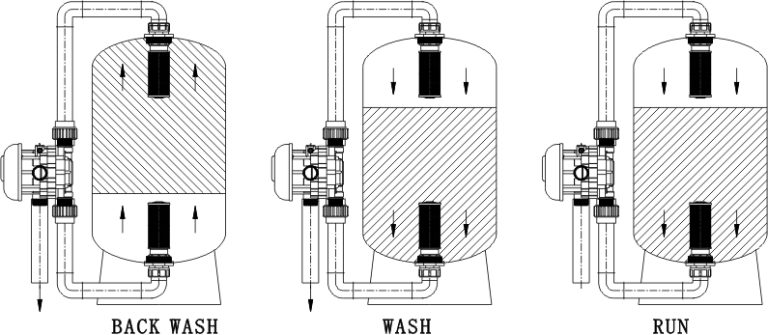

If you are experiencing issues with water flow through the bypass valve, there may be a blockage in the valve’s internal passages. To troubleshoot this problem, first, shut off the water supply to the valve and disconnect it from the system. Inspect the internal passages for any obstructions, such as debris or mineral buildup. Use a brush or compressed air to remove any blockages and ensure that the passages are clear.

If the bypass valve is not diverting water flow as intended, there may be an issue with the valve’s positioning or alignment. Check that the valve is properly installed and aligned with the rest of the system. If necessary, adjust the valve’s position to ensure that it is functioning correctly.

In some cases, the bypass valve may be making unusual noises, such as rattling or humming. This can be a sign of loose components or worn parts within the valve. Inspect the valve for any loose fittings or damaged components and tighten or replace them as needed. Additionally, lubricate the valve to reduce friction and noise during operation.

| fixed\u00a0 bed GR-1 | ||||

| Model | GR2-1/ GR2-1 LCD | GR4-1/ GR4-1 LCD | GR10-1 Top Loading | GR10-1 Side Loading |

| Output Max | 4T/H | 7T/H | 15T/H | 15T/H |

Overall, troubleshooting common issues with Pentair bypass valves requires a systematic approach to identify and address the root cause of the problem. By inspecting the valve for leaks, blockages, alignment issues, and unusual noises, you can effectively diagnose and resolve any issues that may arise. With proper maintenance and care, Pentair bypass valves can continue to function efficiently and effectively in your water treatment system.