“Secure connections for seamless airflow.”

Pros and Cons of Plastic Air Line Push Connectors

Plastic air line push connectors are a popular choice for many industries due to their ease of use and cost-effectiveness. These connectors are designed to quickly and securely connect air lines without the need for tools or clamps, making them a convenient option for a wide range of applications. However, like any product, plastic air line push connectors have their pros and cons that should be considered before making a purchasing decision.

One of the main advantages of plastic air line push connectors is their simplicity. These connectors can be easily installed by simply pushing the air line into the connector until it clicks into place. This eliminates the need for specialized tools or equipment, saving time and effort during installation. Additionally, plastic air line push connectors are lightweight and compact, making them easy to transport and store.

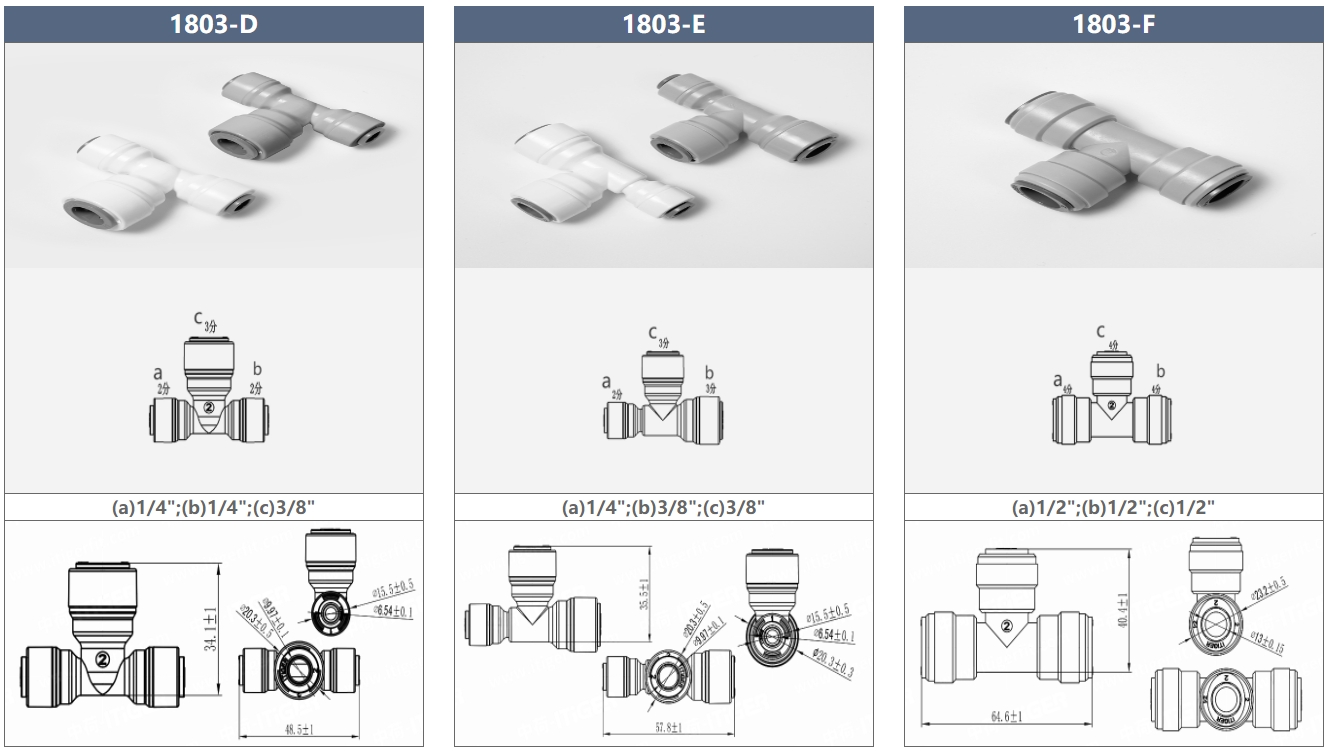

Another benefit of plastic air line push connectors is their versatility. These connectors are available in a variety of sizes and configurations, allowing them to be used in a wide range of applications. Whether you are connecting air lines in a pneumatic system or a compressed air tool, plastic air line push connectors can provide a reliable and secure connection.

In addition to their ease of use and versatility, plastic air line push connectors are also cost-effective. These connectors are typically more affordable than metal connectors, making them a budget-friendly option for businesses looking to save money on their equipment purchases. Despite their lower cost, plastic air line push connectors are still durable and reliable, providing a long-lasting solution for air line connections.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/21 |

However, there are some drawbacks to using plastic air line push connectors that should be taken into consideration. One of the main concerns with plastic connectors is their durability. While these connectors are designed to withstand normal operating conditions, they may not be as robust as metal connectors and could be more prone to wear and tear over time. This could result in leaks or other issues that may require maintenance or replacement.

Another potential downside of plastic air line push connectors is their temperature limitations. Plastic connectors may not be suitable for use in high-temperature environments, as they could melt or deform under extreme heat. This could limit the applications in which plastic air line push connectors can be used, making them less versatile than metal connectors in certain situations.

Despite these drawbacks, plastic air line push connectors remain a popular choice for many industries due to their ease of use, versatility, and cost-effectiveness. By weighing the pros and cons of plastic air line push connectors, businesses can make an informed decision about whether these connectors are the right choice for their specific needs. Whether you are looking for a quick and convenient solution for connecting air lines or a budget-friendly option for your equipment, plastic air line push connectors may be the ideal choice for your application.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/38 |