“Streamline your connections with our plastic terminal strips.”

Table of Contents

Benefits of Using Plastic Terminal Strips in Electrical Wiring

Plastic terminal strips are a common component in electrical wiring systems, providing a convenient and efficient way to connect multiple wires together. These strips are made from durable and lightweight plastic materials, making them ideal for a wide range of applications in both residential and commercial settings. In this article, we will explore the benefits of using plastic terminal strips in electrical wiring, highlighting their versatility, ease of use, and cost-effectiveness.

One of the key advantages of plastic terminal strips is their versatility. These strips come in various sizes and configurations, allowing for easy customization to suit different wiring needs. Whether you are working on a small DIY project or a large-scale electrical installation, plastic terminal strips can be easily adapted to accommodate the specific requirements of the job. This flexibility makes them a popular choice among electricians and hobbyists alike, as they can be used in a wide range of applications without the need for specialized tools or equipment.

In addition to their versatility, plastic terminal strips are also incredibly easy to use. The strips feature multiple screw terminals that can securely hold wires in place, making it simple to create secure and reliable connections. This ease of use is especially beneficial for those who may not have extensive experience with electrical wiring, as plastic terminal strips provide a straightforward and user-friendly solution for connecting wires together. With just a few simple steps, users can quickly and easily create organized and efficient wiring setups using plastic terminal strips.

Furthermore, plastic terminal strips are a cost-effective option for electrical wiring projects. Compared to other types of terminal blocks, such as metal or ceramic strips, plastic terminal strips are typically more affordable while still offering reliable performance. This makes them an attractive choice for those looking to save money on materials without compromising on quality. Additionally, the durability of plastic terminal strips ensures that they can withstand the rigors of everyday use, providing long-lasting performance and reliability for years to come.

Another benefit of using plastic terminal strips in electrical wiring is their lightweight construction. Unlike metal terminal blocks, which can be heavy and cumbersome to work with, plastic terminal strips are lightweight and easy to handle. This makes them ideal for installations in tight spaces or hard-to-reach areas, where maneuverability is essential. The lightweight design of plastic terminal strips also makes them easier to transport and store, further adding to their convenience and practicality.

In conclusion, plastic terminal strips offer a range of benefits for electrical wiring projects, including versatility, ease of use, cost-effectiveness, and lightweight construction. Whether you are a professional electrician or a DIY enthusiast, plastic terminal strips provide a reliable and efficient solution for connecting wires together in a variety of applications. With their durable and user-friendly design, plastic terminal strips are a valuable addition to any electrical wiring toolkit, offering a simple and effective way to create secure and organized connections.

How to Properly Install and Maintain Plastic Terminal Strips in Industrial Settings

Plastic terminal strips are a common component in industrial settings, used for connecting and organizing electrical wires. Proper installation and maintenance of these terminal strips are crucial to ensure the safety and efficiency of the electrical system. In this article, we will discuss the steps to properly install and maintain plastic terminal strips in industrial settings.

When installing plastic terminal strips, it is important to first select the appropriate size and type of terminal strip for the application. Consider factors such as the voltage and current ratings of the electrical system, as well as the number of connections that need to be made. Once the appropriate terminal strip has been selected, ensure that it is securely mounted to a stable surface using the provided mounting holes.

Next, carefully strip the insulation from the ends of the wires that will be connected to the terminal strip. It is important to strip the wires to the correct length to ensure a proper connection. Use a wire stripper tool to remove the insulation, being careful not to damage the conductors inside the wire. Once the wires are stripped, insert them into the appropriate terminals on the terminal strip and tighten the screws to secure the connections.

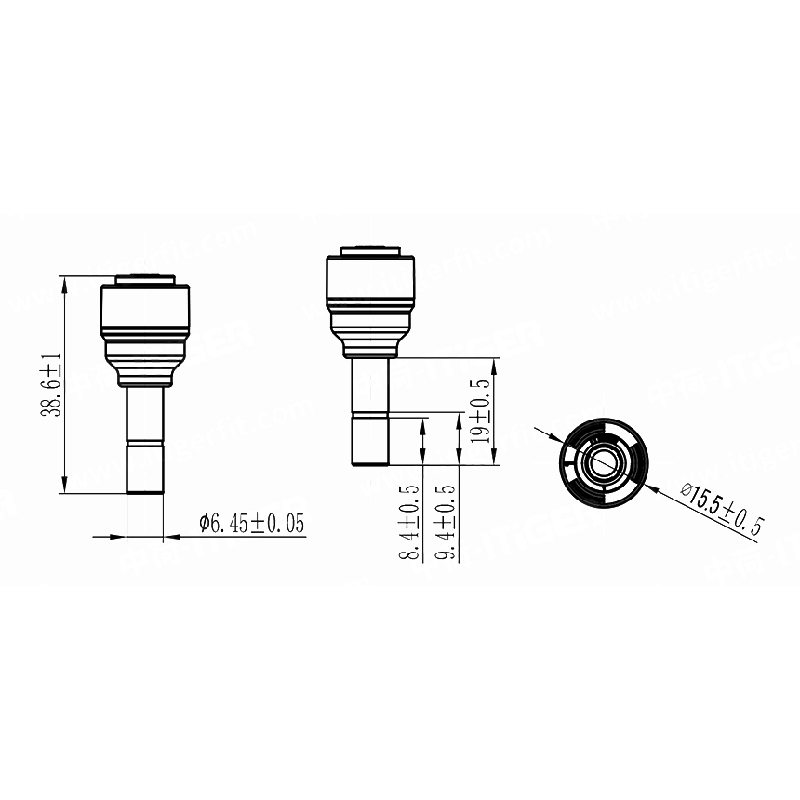

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/36 |

After all the wires have been connected to the terminal strip, it is important to check for any loose connections or exposed wires. Loose connections can lead to overheating and potential electrical hazards, so it is crucial to ensure that all connections are secure. Use a multimeter to check for continuity between the wires and terminals to verify that the connections are properly made.

In addition to proper installation, regular maintenance of plastic terminal strips is essential to ensure their longevity and reliability. Inspect the terminal strips periodically for signs of wear or damage, such as cracked plastic or loose terminals. Replace any damaged terminal strips immediately to prevent electrical failures or safety hazards.

To maintain the cleanliness of the terminal strips, use a soft brush or compressed air to remove any dust or debris that may have accumulated on the terminals. Dust and debris can cause poor connections and increase the risk of electrical faults, so it is important to keep the terminal strips clean and free of obstructions.

In conclusion, proper installation and maintenance of plastic terminal strips are essential in industrial settings to ensure the safety and efficiency of the electrical system. By following the steps outlined in this article, you can ensure that your terminal strips are installed correctly and maintained properly. Remember to select the appropriate terminal strip for the application, securely mount it to a stable surface, make proper connections, and regularly inspect and clean the terminal strips to prevent electrical failures. By taking these precautions, you can ensure the reliable operation of your electrical system and minimize the risk of safety hazards.