Table of Contents

The Importance of ph meter in Wine Making Process

The ph meter is a crucial tool in the wine making process, as it allows winemakers to monitor and control the acidity levels of their wine. pH, which stands for potential of hydrogen, is a measure of the acidity or alkalinity of a solution. In the context of winemaking, pH plays a significant role in determining the overall quality and stability of the wine.

One of the key reasons why pH is so important in winemaking is because it affects the taste, color, and aroma of the wine. The ideal pH range for wine is typically between 3.0 and 4.0, with most wines falling within this range. If the pH of the wine is too high or too low, it can result in off-flavors, cloudiness, and instability. By using a ph meter, winemakers can accurately measure the pH of their wine and make adjustments as needed to ensure that it falls within the optimal range.

In addition to affecting the sensory characteristics of the wine, pH also plays a role in the fermentation process. Yeast, which is responsible for converting sugar into alcohol during fermentation, is sensitive to pH levels. If the pH of the wine is too high or too low, it can inhibit the growth of yeast and slow down the fermentation process. By monitoring the pH of the wine throughout fermentation, winemakers can ensure that the yeast is able to thrive and complete the fermentation process in a timely manner.

Another important aspect of pH in winemaking is its impact on the stability of the wine. pH can influence the growth of bacteria and spoilage organisms in wine, as well as the effectiveness of sulfites as a preservative. By maintaining the pH of the wine within the optimal range, winemakers can help prevent spoilage and ensure that the wine remains stable during storage and aging.

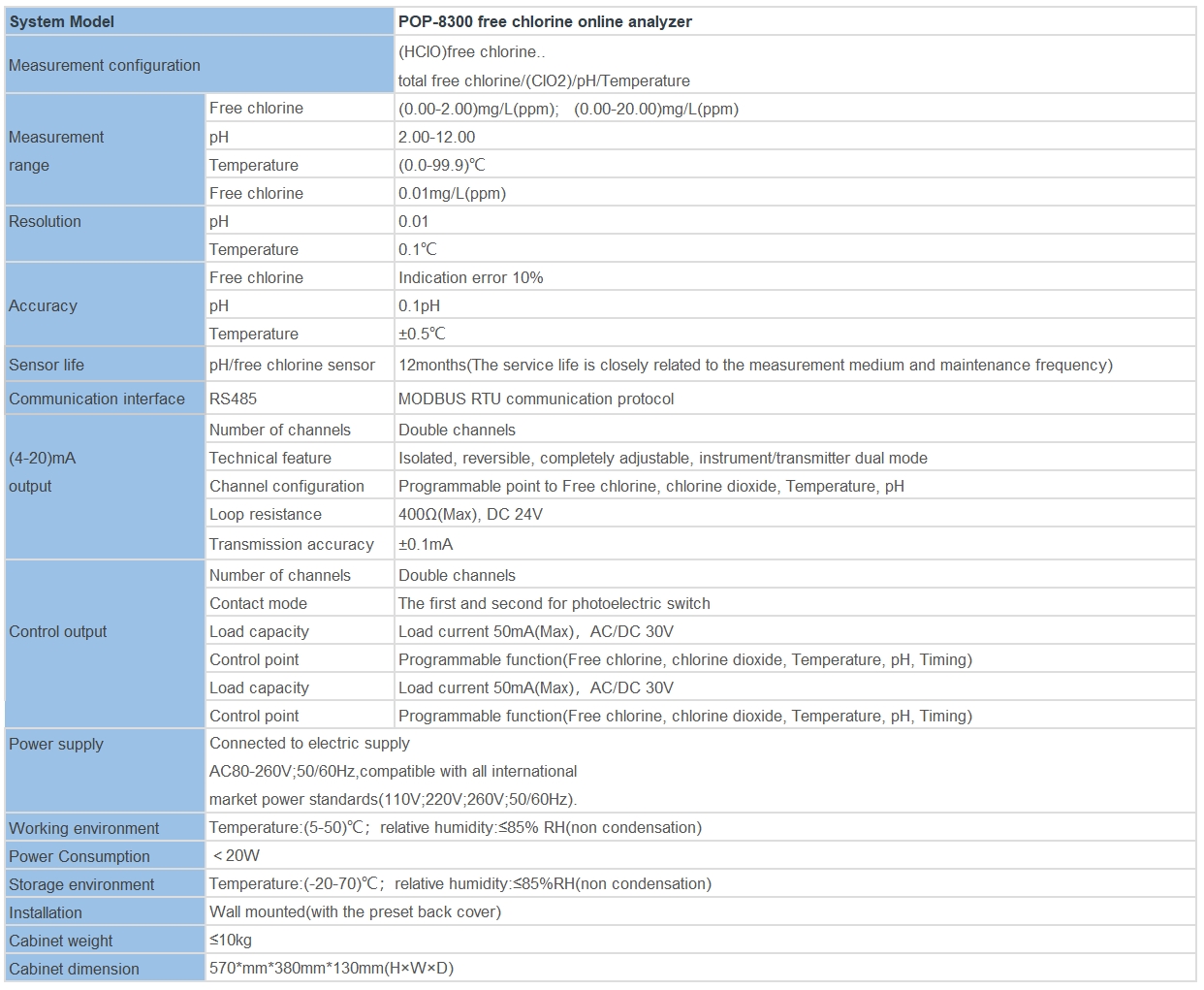

| Model | CM-230S Ecomonical conductivity monitor |

| Range | 0-200/2000/4000/10000uS/cm |

| 0-100/1000/2000/5000PPM | |

| Accuracy | 1.5%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25℃ |

| Oper. Temp. | Normal 0~50℃; High temp 0~120℃ |

| Sensor | Standard:ABS C=1.0cm-1 (others are optional) |

| Display | LCD Screen |

| Zero Correction | Manual correction for low range 0.05-10ppm Set from ECO |

| Unit Display | uS/cm or PPM |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 48×96×100mm(H×W×L) |

| Hole Size | 45×92mm(H×W) |

| Installation Mode | Embedded |

Using a ph meter in the winemaking process is relatively simple. Winemakers can take a small sample of the wine, place it in a clean container, and insert the ph meter probe into the sample. The ph meter will then display the pH reading, allowing the winemaker to make any necessary adjustments to the wine.

How to Properly Calibrate and Use a ph meter for Wine Production

When it comes to producing high-quality wine, one of the most important factors to consider is the pH level of the wine. pH is a measure of the acidity or alkalinity of a solution, and it plays a crucial role in determining the taste, color, and stability of the wine. To ensure that your wine is of the highest quality, it is essential to use a ph meter to accurately measure and monitor the pH levels throughout the winemaking process.

Before using a ph meter for wine production, it is crucial to properly calibrate the device to ensure accurate readings. Calibration is the process of adjusting the ph meter to a known standard solution to ensure that it is providing accurate and reliable measurements. To calibrate a ph meter for wine production, you will need two standard buffer solutions with known pH values, typically pH 4.01 and pH 7.00.

| Model | pH/ORP-8500A pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP:(-1999~+1999)mV; Temp.:(0.0~100.0)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | NTC10K Temperature compensation |

| Medium Temp. | (0~80)°C |

| Analog output | Double channels isolated; transportable(4~20)mA, instruments/ transmitter mode |

| Control Output | Triple channels semiconductor photoelectric switch, load current: AC/DC 30V, 50mA(max) |

| Communication port | RS485,Modbus RTU protocol |

| Working Environment | Temp.(0~80)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx94mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

To begin the calibration process, first, rinse the electrode of the ph meter with distilled water to remove any residue. Next, immerse the electrode in the pH 7.00 buffer solution and allow it to stabilize for a few minutes. Once the reading on the ph meter stabilizes, adjust the calibration knob on the device until it reads the correct pH value of 7.00. Rinse the electrode with distilled water again and repeat the process with the pH 4.01 buffer solution. Once both buffer solutions have been used to calibrate the ph meter, the device is ready to use for wine production.

When using a ph meter for wine production, it is essential to properly prepare the wine sample for testing. To do this, first, ensure that the wine sample is at room temperature, as temperature can affect the accuracy of pH measurements. Next, gently stir the wine sample to ensure that it is well mixed and homogeneous. Carefully insert the electrode of the ph meter into the wine sample, making sure that it is fully submerged and not touching the sides of the container.

Once the electrode is properly immersed in the wine sample, allow it to stabilize for a few moments until the reading on the ph meter stabilizes. Take note of the pH reading on the device, as this will provide valuable information about the acidity of the wine. pH levels in wine typically range from 3.0 to 4.0, with most wines falling within the range of 3.2 to 3.6. Monitoring the pH levels of the wine throughout the winemaking process can help you make informed decisions about adjustments that may be needed to achieve the desired taste and quality of the final product.

In conclusion, using a ph meter for wine production is essential for ensuring that your wine is of the highest quality. By properly calibrating the ph meter and following the correct procedures for testing wine samples, you can accurately monitor the acidity of the wine and make informed decisions about adjustments that may be needed during the winemaking process. By paying close attention to pH levels, you can produce wines that are well-balanced, flavorful, and stable, ensuring a superior product that will delight your customers and stand out in the competitive wine market.