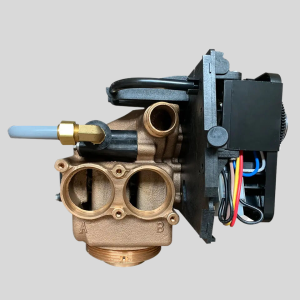

FLECK Control Valve 9500

Easily-adjustable, 5-cycle, downflow-brining control

Rugged, long-life construction features a lead-free brass valve body

Uses conditioned water for regeneration

Easily-adjustable, 5-cycle, downflow-brining control

Rugged, long-life construction features a lead-free brass valve body

Uses conditioned water for regeneration

“One Dynamic and Two Static” Double Static Ceramics Plates Multi-port Valve is on behalf of another beginning in the field of water treatment control, which can overcome many disadvantages of traditional products in installation.

Widely used for online measurement of acid&alkali in low concentrations and the low viscosity single-phase fluid of non-trade settlement process.

1) Automatic softener valve Downflow and upflow type.

2) Downflow & Upflow Working Position :

a) Service->Back Wash->Downflow Brine and slow rinse->Refill ->Fast rinse->Service.

b) Service->Back Wash->Upflow Brine and slow rinse->Refill ->Fast rinse->Service.

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly.

Incorporates 2 time-tested, hydraulically-balanced pistons to independently pilot service flow and regeneration

For use with single or multiple tank systems

Backwashes softener tanks up to 36″ diameter

Continuous flow rate of 106 GPM

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

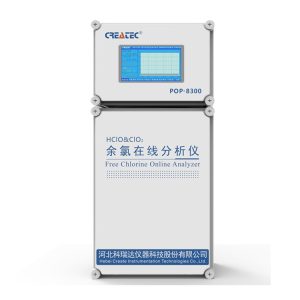

Applicable to all kinds of small and medium-sized single-stage, double-stage reverse osmosis control system. With simple operation, complete measurement and configuration, highly integrated system

1). Automatic advance water softener valve Upflow type with empty salt cabinet technology.

2). Upflow Working Position :

a). Refill before regeneration: Service->Refill the softener water->Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Service .

b). Refill after regeneration: Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Refill the softener water->Service .

3). Using ceramic moving valve disk, small rotation torque.

4). Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5). It could be operated with pressure directly