Importance of Using a Water Test Kit for Brewing Beer

Water is a crucial ingredient in the brewing process, making up about 90% of beer. The quality of water used can greatly impact the taste, aroma, and overall quality of the final product. This is why it is essential for brewers to test their water before brewing to ensure that it meets the necessary standards. One way to do this is by using a water test kit specifically designed for brewing.

| Model | pH/ORP-8500A pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP:(-1999~+1999)mV; Temp.:(0.0~100.0)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | NTC10K Temperature compensation |

| Medium Temp. | (0~80)°C |

| Analog output | Double channels isolated; transportable(4~20)mA, instruments/ transmitter mode |

| Control Output | Triple channels semiconductor photoelectric switch, load current: AC/DC 30V, 50mA(max) |

| Communication port | RS485,Modbus RTU protocol |

| Working Environment | Temp.(0~80)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx94mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

These water test kits are designed to measure various parameters in water that can affect the brewing process, such as pH, hardness, alkalinity, and chlorine levels. By testing for these parameters, brewers can ensure that their water is suitable for brewing and make any necessary adjustments to achieve the desired results.

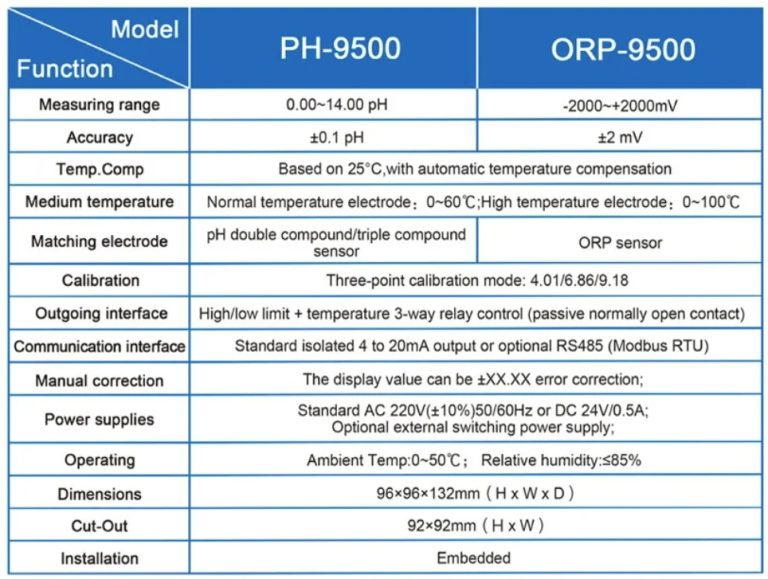

| Model | pH/ORP-9500 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~50℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit triple relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×132mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

One of the most important parameters to test for is pH. The pH of water can have a significant impact on the flavor of the beer, as it can affect the activity of enzymes and the solubility of minerals. Most brewing water should have a pH between 5.2 and 5.6 for optimal brewing conditions. A water test kit can help brewers determine the pH of their water and make adjustments if necessary.

Another important parameter to test for is hardness. Hard water contains high levels of minerals such as calcium and magnesium, which can affect the flavor and clarity of the beer. By testing for hardness, brewers can determine if they need to soften their water or add minerals to achieve the desired brewing conditions.

Alkalinity is another important parameter to test for when brewing beer. Alkalinity can affect the pH of the water and the final product, as well as the efficiency of the mash. By testing for alkalinity, brewers can make adjustments to ensure that their water is suitable for brewing.

Chlorine levels are also important to test for when brewing beer. Chlorine can react with compounds in the beer to produce off-flavors and aromas. By testing for chlorine levels, brewers can determine if they need to treat their water to remove chlorine before brewing.

Using a water test kit for brewing is essential for ensuring that the water used in the brewing process meets the necessary standards. By testing for parameters such as pH, hardness, alkalinity, and chlorine levels, brewers can make adjustments to their water to achieve the desired brewing conditions and produce high-quality beer.

In conclusion, water is a crucial ingredient in the brewing process, and the quality of water used can greatly impact the final product. By using a water test kit specifically designed for brewing, brewers can test for parameters such as pH, hardness, alkalinity, and chlorine levels to ensure that their water meets the necessary standards. Testing for these parameters and making any necessary adjustments can help brewers achieve the desired brewing conditions and produce high-quality beer.