Table of Contents

Pros and Cons of push fit Stop End for 15mm Distributors

push fit stop ends for 15mm distributors are a popular choice for plumbing projects due to their ease of use and efficiency. These fittings provide a convenient way to cap off pipes without the need for soldering or special tools, making them a convenient option for both DIY enthusiasts and professional plumbers. However, like any plumbing fitting, push fit stop ends have their own set of pros and cons that should be considered before making a purchase.

One of the key advantages of push fit stop ends is their simplicity and ease of installation. These fittings can be quickly and easily pushed onto the end of a 15mm pipe, creating a secure and watertight seal without the need for additional materials or equipment. This makes them ideal for situations where time is of the essence or when working in tight spaces where traditional soldering methods may be impractical.

Additionally, push fit stop ends are reusable, allowing for easy removal and reinstallation if needed. This can be particularly useful during renovation projects or when making adjustments to existing plumbing systems. The ability to quickly and easily disconnect and reconnect these fittings can save time and effort, making them a versatile option for a wide range of applications.

On the other hand, push fit stop ends may not be suitable for all situations. While they are generally reliable and secure, some users may have concerns about the long-term durability of these fittings compared to traditional soldered connections. In some cases, push fit fittings may be more prone to leaks or failures over time, especially in high-pressure or high-temperature applications.

Another potential downside of push fit stop ends is their cost. While these fittings are generally affordable and widely available, they may be more expensive than traditional soldered fittings in the long run. Additionally, some users may find that push fit stop ends are not as aesthetically pleasing as soldered connections, especially in visible or exposed plumbing installations.

In conclusion, push fit stop ends for 15mm distributors offer a convenient and efficient way to cap off pipes without the need for soldering or special tools. These fittings are easy to install, reusable, and versatile, making them a popular choice for many plumbing projects. However, users should be aware of the potential drawbacks of push fit fittings, including concerns about long-term durability and cost. Ultimately, the decision to use push fit stop ends will depend on the specific requirements of the project and the preferences of the individual user.

How to Install a push fit Stop End on a 15mm Distributor

push fit stop ends are essential components in plumbing systems, particularly when it comes to sealing off pipes and preventing leaks. If you’re looking to install a push fit stop end on a 15mm distributor, you’re in the right place. This article will guide you through the step-by-step process to ensure a successful installation.

First and foremost, it’s crucial to gather all the necessary tools and materials before beginning the installation process. You will need a push fit stop end specifically designed for 15mm pipes, a pipe cutter, and possibly some pipe inserts if required. Once you have everything you need, you can proceed with the installation.

To start, make sure to turn off the water supply to the pipe you’ll be working on. This is a crucial step to prevent any water leakage during the installation process. Next, use a pipe cutter to cut the pipe cleanly and squarely where you intend to install the push fit stop end. It’s important to ensure that the cut is straight to guarantee a proper fit.

After cutting the pipe, check for any burrs or rough edges that could affect the sealing of the push fit stop end. Use a deburring tool or sandpaper to smooth out any imperfections and ensure a clean surface for the fitting. Once the pipe is prepped and ready, you can insert any necessary pipe inserts into the pipe to provide additional support and reinforcement.

Now comes the main part of the installation process – fitting the push fit stop end onto the pipe. Simply push the stop end onto the pipe until it reaches the desired position. You should feel a slight resistance as the fitting securely locks into place. Make sure to double-check that the stop end is fully inserted and seated correctly to prevent any potential leaks in the future.

Once the push fit stop end is securely in place, you can turn the water supply back on and check for any leaks around the fitting. It’s a good idea to inspect the area carefully and run some water through the pipe to ensure that everything is functioning as it should. If you notice any leaks or issues, turn off the water supply immediately and reevaluate the fitting.

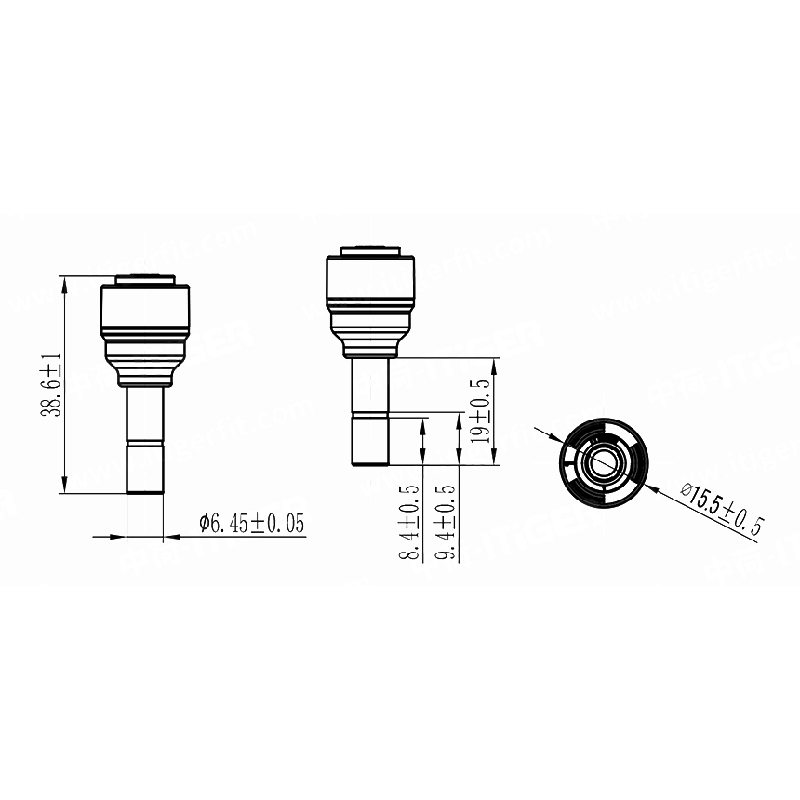

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/36 |

In conclusion, installing a push fit stop end on a 15mm distributor is a relatively straightforward process that can be completed with the right tools and a bit of know-how. By following the steps outlined in this article, you can effectively seal off your pipes and maintain a leak-free plumbing system. Remember to always double-check your work and seek professional assistance if needed to ensure a successful installation.