Table of Contents

Benefits of Using Flow Sensor Krohne in Industrial Applications

Flow sensors are essential components in various industrial applications, providing accurate measurements of liquid flow rates. One of the leading manufacturers of flow sensors is Krohne, a company known for its high-quality products and innovative technology. In this article, we will explore the benefits of using flow sensor Krohne in industrial applications.

One of the key advantages of using Krohne flow sensors is their accuracy. These sensors are designed to provide precise measurements of flow rates, ensuring that industrial processes run smoothly and efficiently. With Krohne flow sensors, operators can rely on accurate data to make informed decisions and optimize their operations.

Furthermore, Krohne flow sensors are easy to install and maintain, reducing the time and effort required for maintenance tasks. With simple installation procedures and user-friendly interfaces, operators can quickly set up and calibrate Krohne flow sensors without the need for specialized training.

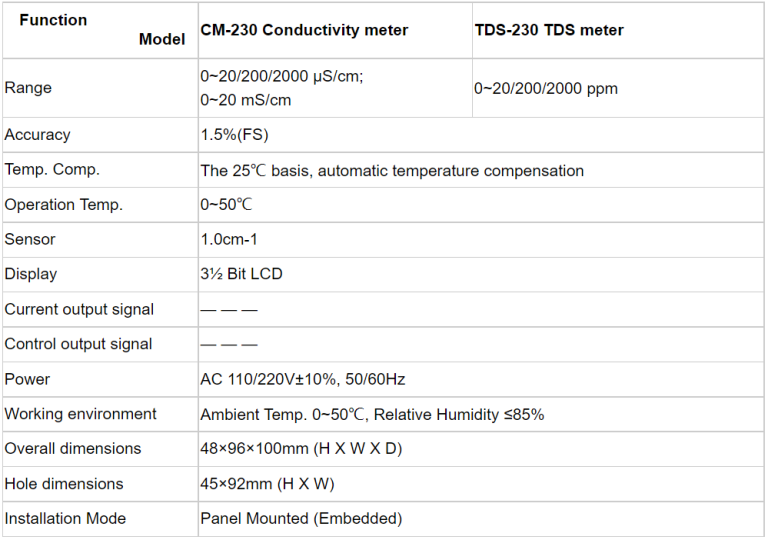

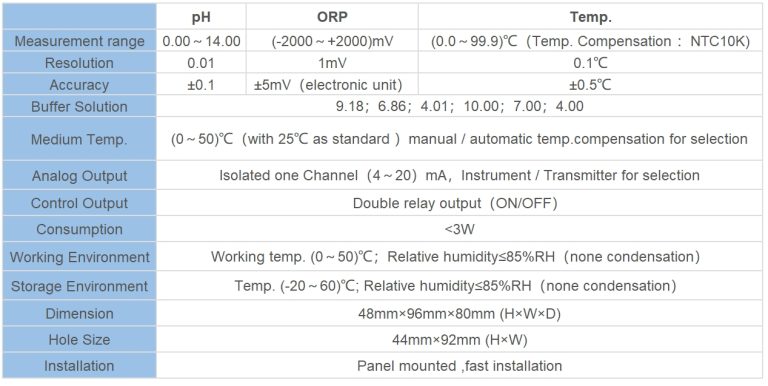

| model | pH/ORP-5500 series pH/ORP online transmitting controller | |

| Measurement range | pH | 0.00~14.00 |

| ORP | -2000mV~2000mV | |

| Temp. | ( 0.0~50.0)℃ (temperature compensation component:NTC10K) | |

| Resolution | pH | 0.01 |

| ORP | 1mV | |

| Temp. | 0.1℃ | |

| accuracy | pH | 0.1 |

| ORP | ±5mV(electronic unit) | |

| Temp. | ±0.5℃ | |

| Approximate input impedance | 3×1011Ω | |

| Buffer solution | pH value: 10.00;9.18;7.00;6.86;4.01;4.00 | |

| Temp. compensation range | (0~50)℃(with 25℃ as standard)Manual and automatic temperature compensation | |

| (4~20)mA | characteristics | Isolated,fully adjustable,reverible,instrument/transmitter for selection |

| Loop resistance | 500Ω(Max),DC 24V | |

| accuracy | ±0.1mA | |

| Control contact | Electrical contacts | Double relay SPST-NO,return model |

| Loop capacity | AC 220V/AC 110V 2A(Max);DC 24V 2A(Max) | |

| Power consumption | <3W | |

| Working environment | temperature | (0~50)℃ |

| humidity | ≤85%RH(none condensation) | |

| Storage environment | Temp.(-20-60) ℃;relative humidity:≤85%RH(none condensation | |

| Outline dimension | 96mm×96mm×105mm(H×W×D) | |

| Hole dimension | 91mm×91mm(H×W) | |

| installation | Panel mounted,fast installation | |

Moreover, Krohne flow sensors are designed to be energy-efficient, helping industrial operators reduce their overall energy consumption and operating costs. By accurately measuring flow rates and optimizing processes, Krohne flow sensors can help companies improve their efficiency and sustainability.

In conclusion, Krohne flow sensors offer a range of benefits for industrial applications, including accuracy, durability, versatility, ease of installation and maintenance, and energy efficiency. By choosing Krohne flow sensors, industrial operators can improve their operations, reduce downtime, and save on operating costs. With their reputation for quality and innovation, Krohne flow sensors are a reliable choice for companies looking to optimize their industrial processes.

How to Properly Calibrate and Maintain Flow Sensor Krohne Devices

Flow sensors are essential devices used in various industries to measure the flow rate of liquids and gases. One popular brand known for its high-quality flow sensors is Krohne. Krohne flow sensors are known for their accuracy and reliability, making them a popular choice among engineers and technicians.

Proper calibration and maintenance of flow sensors are crucial to ensure accurate and consistent measurements. In this article, we will discuss how to properly calibrate and maintain Krohne flow sensors to ensure optimal performance.

Calibration is the process of adjusting the flow sensor to ensure accurate measurements. It is essential to calibrate flow sensors regularly to account for any drift or changes in the sensor’s performance over time. Krohne flow sensors typically come with calibration instructions from the manufacturer, which should be followed closely.

Before calibrating a Krohne flow sensor, it is essential to ensure that the sensor is clean and free from any debris or buildup that could affect its performance. Cleaning the sensor with a mild detergent and water can help remove any contaminants that may interfere with the calibration process.

Once the sensor is clean, the next step is to connect it to a calibration device or system. Krohne flow sensors are typically calibrated using a reference standard or calibration equipment provided by the manufacturer. The calibration process involves comparing the sensor’s measurements to the reference standard and making adjustments as needed to ensure accuracy.

During the calibration process, it is essential to follow the manufacturer’s instructions carefully and make any necessary adjustments to the sensor’s settings. This may involve adjusting the zero point, span, or other parameters to ensure accurate measurements. Once the calibration is complete, it is essential to document the results and any adjustments made for future reference.

In addition to calibration, proper maintenance of Krohne flow sensors is essential to ensure long-term performance and reliability. Regular maintenance can help prevent issues such as sensor drift, buildup, or damage that could affect the sensor’s accuracy.

| Model | POP-8300 free chlorine online analyzer |

| Measurement range | (0.00-2.00)mg/L(ppm) (0.00-20.00)mg/L(ppm) |

| Accuracy | Indication error 10% |

| Resolution | 0.01mg/L(ppm) |

| Communication interface | RS485 MODBUS RTU communication protocol |

| Analog output | Double channel (4-20)mA output; Isolated, reversible, completely adjustable, instrument/transmitter dual mode; ±0.1mA transmission accuracy |

| Control output | Double channels, Load capacity 50mA(Max),AC/DC 30V |

| Power supply | Connected to electric supply AC80-260V;50/60Hz, compatible with all international market power standards(110V;220V;260V;50/60Hz). |

| Working environment | Temperature:(5-50)℃;relative humidity:≤85% RH(non-condensation) |

| Power Consumption | <20W |

| Storage environment | Temperature:(-20-70)℃;relative humidity:≤85%RH(non-condensation) |

| Installation | Wall mounted (with the preset back cover) |

| Cabinet weight | ≤10kg |

| Cabinet dimension | 570*mm*380mm*130mm(H×W×D) |

One essential aspect of maintaining Krohne flow sensors is to regularly inspect the sensor for any signs of damage or wear. This includes checking for cracks, leaks, or other physical damage that could affect the sensor’s performance. If any damage is found, it is essential to address it promptly to prevent further issues.

Another critical aspect of maintaining Krohne flow sensors is to regularly clean the sensor to remove any buildup or contaminants that could affect its performance. Cleaning the sensor with a mild detergent and water can help remove any debris or buildup that may interfere with the sensor’s measurements.

In conclusion, proper calibration and maintenance of Krohne flow sensors are essential to ensure accurate and reliable measurements. By following the manufacturer’s instructions for calibration and regularly inspecting and cleaning the sensor, you can help ensure optimal performance and longevity of your Krohne flow sensor. Remember to document the calibration results and any maintenance performed for future reference.