Table of Contents

Benefits of Upgrading to Runxin F67C1 for Water Treatment Systems

Water treatment systems are essential for ensuring clean and safe drinking water for households, businesses, and communities. One key component of these systems is the control valve, which regulates the flow of water and helps to remove impurities. The Runxin F67C1 is a popular choice for control valves in water treatment systems due to its efficiency and reliability. In this article, we will explore the benefits of upgrading to the Runxin F67C1 for water treatment systems.

One of the main advantages of the Runxin F67C1 is its durability. Made from high-quality materials, this control valve is built to last and can withstand the rigors of continuous use in water treatment systems. This durability not only ensures a longer lifespan for the valve but also reduces the need for frequent maintenance and repairs, saving time and money in the long run.

In addition to its durability, the Runxin F67C1 is also known for its efficiency. With its precise control over the flow of water, this valve helps to optimize the performance of water treatment systems, ensuring that impurities are effectively removed and water quality is maintained at a high standard. This efficiency not only improves the overall effectiveness of the system but also helps to reduce water wastage, making it a more sustainable choice for water treatment.

Another benefit of upgrading to the Runxin F67C1 is its versatility. This control valve is compatible with a wide range of water treatment systems, making it a versatile option for both residential and commercial applications. Whether you are looking to upgrade an existing system or install a new one, the Runxin F67C1 can easily be integrated to meet your specific needs and requirements.

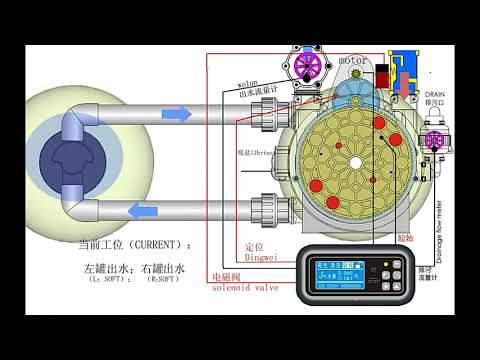

Furthermore, the Runxin F67C1 is designed with user convenience in mind. With its user-friendly interface and easy-to-use controls, this valve makes it simple for operators to monitor and adjust the flow of water in the system. This ease of use not only improves the overall efficiency of the system but also reduces the risk of human error, ensuring consistent and reliable performance.

| Category | Model | Inlet/Outlet | Drain | Base | Riser Pipe | Water Capacity m3/h |

| automatic filter valve | AF2 | 3/4″, 1″ | 3/4″ | 2.5″ | 1.05″ OD | 2 |

| AF2-H | 3/4″, 1″ | 1/2″ | 2.5″ | 1.05″ OD | 2 | |

| AF4 | 1″ | 1″ | 2.5″ | 1.05″ OD | 4 | |

| AF10 | 2″ | 1″ | 4″ | 1.5″D-GB | 10 |

In conclusion, upgrading to the Runxin F67C1 for water treatment systems offers a range of benefits, including durability, efficiency, versatility, and user convenience. By investing in this high-quality control valve, you can improve the performance of your water treatment system, reduce maintenance costs, and ensure clean and safe drinking water for your home or business. Consider upgrading to the Runxin F67C1 today and experience the difference it can make in your water treatment system.

Troubleshooting Common Issues with Runxin F67C1 Control Valves

Runxin F67C1 control valves are widely used in various industries for controlling the flow of liquids. However, like any mechanical device, these control valves can sometimes experience issues that may affect their performance. In this article, we will discuss some common problems that users may encounter with Runxin F67C1 control valves and provide troubleshooting tips to help resolve them.

One of the most common issues with Runxin F67C1 control valves is leakage. Leakage can occur due to a variety of reasons, such as worn out seals, loose fittings, or improper installation. To troubleshoot this issue, start by checking the seals and fittings for any signs of wear or damage. If you notice any issues, replace the seals or tighten the fittings as needed. Additionally, make sure that the control valve is installed correctly and that all connections are secure to prevent leakage.

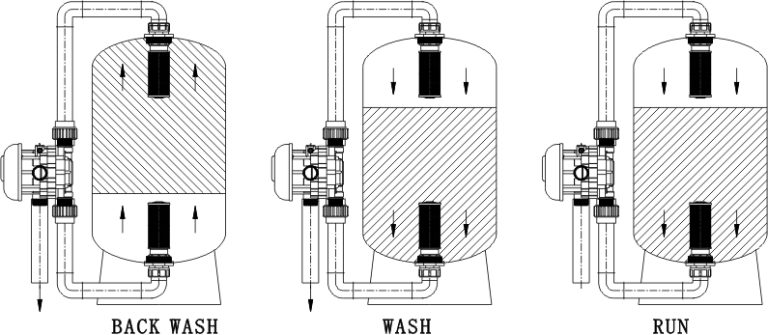

Another common problem with Runxin F67C1 control valves is erratic flow control. Erratic flow control can be caused by a number of factors, including clogged filters, air pockets in the system, or a malfunctioning control valve. To troubleshoot this issue, start by checking the filters and cleaning or replacing them if necessary. Next, check for any air pockets in the system and bleed them out to ensure smooth flow control. If the issue persists, inspect the control valve for any signs of damage or malfunction and repair or replace it as needed.

In some cases, users may experience issues with the control valve not responding to input signals. This can be caused by a faulty actuator, wiring issues, or a malfunctioning control board. To troubleshoot this issue, start by checking the actuator for any signs of damage or wear and replace it if necessary. Next, inspect the wiring connections to ensure they are secure and properly connected. If the issue persists, check the control board for any faults or errors and repair or replace it as needed.

Users may also encounter problems with the control valve sticking or jamming. This can be caused by debris or foreign objects getting lodged in the valve, improper lubrication, or worn out components. To troubleshoot this issue, start by inspecting the valve for any debris or foreign objects and remove them if necessary. Next, lubricate the moving parts of the valve to ensure smooth operation. If the issue persists, check for any worn out components and replace them as needed.

In conclusion, Runxin F67C1 control valves are reliable and efficient devices for controlling the flow of liquids in various industries. However, like any mechanical device, they may experience issues from time to time. By following the troubleshooting tips provided in this article, users can effectively address common problems with Runxin F67C1 control valves and ensure optimal performance and reliability. Remember to always consult the manufacturer’s guidelines and recommendations when troubleshooting any issues with control valves to avoid causing further damage or voiding warranties.