Importance of Conductivity Meters in Water Treatment Processes

Conductivity meters play a crucial role in water treatment processes by measuring the ability of water to conduct an electrical current. This measurement is essential for determining the purity of water and ensuring that it meets the required standards for various applications. In this article, we will explore the importance of conductivity meters in water treatment and how they help in maintaining the quality of water.

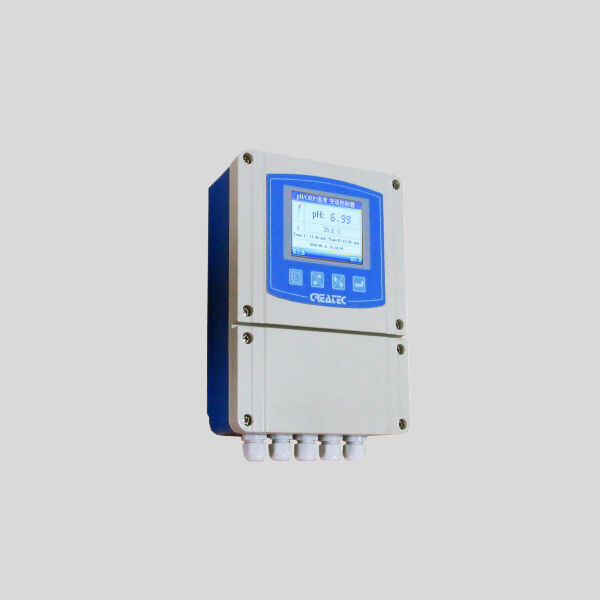

| Model | pH/ORP-510 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Manual/Automatic temperature compensation; No Comp. |

| Oper. Temp. | Normal 0~60℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 48×96×100mm(H×W×L) |

| Hole Size | 45×92mm(H×W) |

| Installation Mode | Embedded |

One of the key reasons why conductivity meters are essential in water treatment is their ability to detect the presence of impurities in water. Conductivity is directly related to the concentration of ions in water, which can come from various sources such as dissolved salts, minerals, and other contaminants. By measuring the conductivity of water, operators can quickly identify any deviations from the desired levels and take corrective actions to remove impurities.

Moreover, conductivity meters are also used to monitor the effectiveness of water treatment processes. For example, in desalination plants, conductivity meters are used to track the removal of salts from seawater. By continuously monitoring the conductivity of water at different stages of the treatment process, operators can ensure that the desired level of purity is achieved before the water is released for consumption or other uses.

| Model | EC-8851/EC-9900 High Precision Conductivity/resistivity controller |

| Range | 0-200/2000/4000/10000uS/cm |

| 0-20/200mS/cm 0-18.25MΩ | |

| Accuracy | Conductivity:1.5%; Resistivity:2.0%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25℃ |

| Oper. Temp. | Normal 0~50℃; High temp 0~120℃ |

| Sensor | 0.01/0.02/0.1/1.0/10.0cm-1 |

| Display | LCD Screen |

| Current Output | 4-20mA output/2-10V/1-5V |

| Output | High/Low limit dual relay control |

| Power | DC24V/0.5A or |

| AC85-265V±10% 50/60Hz | |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×72mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In addition to monitoring water quality, conductivity meters are also used to control the dosage of chemicals in water treatment processes. For instance, in wastewater treatment plants, conductivity meters are used to adjust the dosage of coagulants and flocculants based on the conductivity of the water. This ensures that the right amount of chemicals is added to achieve optimal treatment efficiency without wasting resources.

Furthermore, conductivity meters are essential for maintaining the proper functioning of water treatment equipment. High levels of conductivity can lead to corrosion and scaling in pipes, pumps, and other components of water treatment systems. By monitoring the conductivity of water, operators can prevent these issues and prolong the lifespan of equipment, ultimately reducing maintenance costs and downtime.

Another important aspect of conductivity meters in water treatment is their role in ensuring compliance with regulatory standards. Water quality regulations set limits on the conductivity of water for different uses, such as drinking water, industrial processes, and agricultural irrigation. Conductivity meters help operators to continuously monitor water quality and ensure that it meets the required standards to protect public health and the environment.

In conclusion, conductivity meters are indispensable tools in water treatment processes for monitoring water quality, controlling treatment processes, maintaining equipment, and ensuring regulatory compliance. By providing real-time data on the conductivity of water, these meters help operators to make informed decisions and take proactive measures to ensure the purity and safety of water for various applications. As the demand for clean water continues to grow, the importance of conductivity meters in water treatment will only increase, highlighting the critical role they play in safeguarding our most precious resource.