Table of Contents

Understanding the Role of Valves in Modern Filter Corporations

Valve and Filter Corporation is a term that may not be familiar to many, but it plays a crucial role in various industries. The primary function of a valve is to control the flow of fluids or gases in a system, while a filter’s role is to remove impurities from a substance. Together, they form an integral part of many industrial processes, ensuring efficiency and safety.

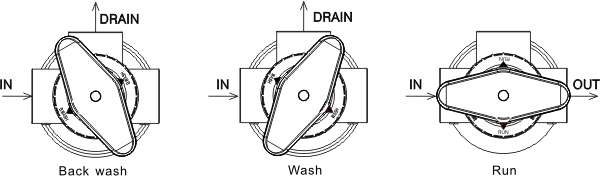

To begin with, valves are mechanical devices that regulate, direct, or control the flow of a fluid by opening, closing, or partially obstructing various passageways. They are essential components in a wide range of applications, from controlling water flow in domestic plumbing systems to regulating gas flow in power plants. In the context of a filter corporation, valves are used to control the flow of fluids or gases through the filters. This allows for precise control over the filtration process, ensuring that the filtered substance meets the required standards.

Moreover, valves come in various types, each designed to perform a specific function. For instance, check valves allow fluid to flow in one direction only, preventing backflow. On the other hand, control valves can adjust the flow rate based on external input, providing a high level of control over the process. The choice of valve depends on the specific requirements of the filtration process.

| Model | MSS2 | ASS2 -LCD/LED |

| Working Position | Service->Back Wash->Upflow Brine and slow rinse-> Fast rinse->Refill the softener water->Service . | |

| Regeneration mode | Manual | Automatic type |

| Meter Delay | ||

| Meter immediate | ||

| Intelligent Meter Delay | ||

| Intelligent Meter Immediate | ||

| Timer by day : 0-99 days | ||

| Timer by hours: 0-99 hours | ||

| Inlet | 3/4” | 3/4” 1” |

| Outlet | 3/4” | 3/4” 1” |

| Drain | 1/2” | 1/2” |

| Base | 2-1/2” | 2-1/2” |

| Riser pipe | 1.05” OD | 1.05” OD |

| Water Capacity | 2m3/h | 2m3/h |

| Working Pressure | 0.15-0.6Mpa | 0.15-0.6Mpa |

| Working Temperature | 5-50° C | |

| Power Supply | No Need Power | AC100-240 / 50-60Hz / DC12V-1.5A |

Transitioning to filters, these are devices that remove impurities from a substance, typically a liquid or gas. They work by allowing the substance to pass through a medium that captures the impurities. In a filter corporation, filters are used in a wide range of applications, from purifying water to filtering air in HVAC systems. The type of filter used depends on the nature of the substance being filtered and the level of purity required.

| Model | AFC2-LCD | AFC2-LED |

| Working Position | Filter->Back wash 1->Back wash 2-> Fast rinse -> Filter | |

| Regeneration mode | Automatic | Automatic |

| Time by day :0-99days | Time by day :0-99days | |

| Time by hours:0-99 hours | Time by hours:0-99 hours | |

| In (inlet of valve) | 1/2”F | 1/2”F |

| I1(inlet of first filter) | 1/2”F | 1/2”F |

| I2(inlet of second filter) | 1/2”F | 1/2”F |

| Drain | 1/2”M | 1/2”M |

| D1( Drain of first filter) | 1/2”M | 1/2”M |

| D2(Drain of second filter) | 1/2”M | 1/2”M |

| Water capacity | 2m3/h | 2m3/h |

| Working pressure | 0.15-0.6Mpa | |

| Power Supply | AC100-240V/ 50-60Hz / DC12V-1.5A | |

In the context of a valve and filter corporation, the integration of valves and filters is crucial. The valves control the flow of the substance into and out of the filters, ensuring that the filtration process is carried out efficiently and effectively. This integration allows for precise control over the filtration process, resulting in a high-quality end product.

Furthermore, the role of valves and filters extends beyond the actual filtration process. They also play a crucial role in maintaining the safety and integrity of the system. For instance, safety valves are used to prevent pressure build-up that could lead to system failure. Similarly, filters help to prevent the contamination of the system, protecting both the equipment and the end product.

In conclusion, valves and filters are integral components of modern filter corporations. They work together to control the flow of substances and remove impurities, ensuring the efficiency, safety, and quality of the process. As technology continues to advance, we can expect to see even greater integration and sophistication in the design and operation of valves and filters, further enhancing their role in the industry.

Innovative Valve Technologies Transforming the Filter Corporation Industry

The valve and filter corporation industry is undergoing a significant transformation, thanks to the advent of innovative valve technologies. These advancements are not only enhancing the efficiency of filtration processes but also contributing to the overall growth and development of the industry.

Valves, the integral components of any filtration system, control the flow of fluids and gases. Their functionality and performance directly impact the effectiveness of the filtration process. Traditional valves, while effective, often fall short in terms of precision, durability, and adaptability. However, the introduction of innovative valve technologies has revolutionized the way these systems operate, offering unprecedented levels of accuracy and reliability.

One of the most notable advancements in this field is the development of smart valves. These technologically advanced valves are equipped with sensors and digital interfaces that allow for real-time monitoring and control. They can automatically adjust the flow rate based on the system’s requirements, thereby optimizing the filtration process. This not only improves the efficiency of the system but also significantly reduces the risk of errors and malfunctions.

Another groundbreaking innovation is the introduction of self-cleaning valves. These valves are designed to automatically remove any accumulated debris or particles, ensuring a smooth and uninterrupted flow. This feature is particularly beneficial in industries where the filtration systems handle large volumes of fluids or gases with high levels of impurities. The self-cleaning valves not only enhance the performance of the system but also extend its lifespan by preventing wear and tear caused by particle accumulation.

The development of corrosion-resistant valves has also made a significant impact on the valve and filter corporation industry. These valves are made from materials that can withstand harsh conditions and corrosive substances, making them ideal for use in industries such as oil and gas, chemical, and wastewater treatment. The corrosion-resistant valves not only offer enhanced durability but also ensure the safety and integrity of the filtration process.

However, the adoption of these technologies also presents certain challenges. The high cost of these advanced valves and the need for specialized skills to operate and maintain them are some of the major hurdles. Despite these challenges, the benefits offered by these innovative valve technologies far outweigh the drawbacks, making them a worthwhile investment for businesses in the valve and filter corporation industry.

In conclusion, the valve and filter corporation industry is witnessing a paradigm shift with the introduction of innovative valve technologies. These advancements are not only transforming the way filtration systems operate but also shaping the future of the industry. As these technologies continue to evolve, they are expected to bring about even more significant changes, paving the way for more efficient, reliable, and sustainable filtration solutions.