Table of Contents

Understanding the Functionality of Water Softener Control Valves

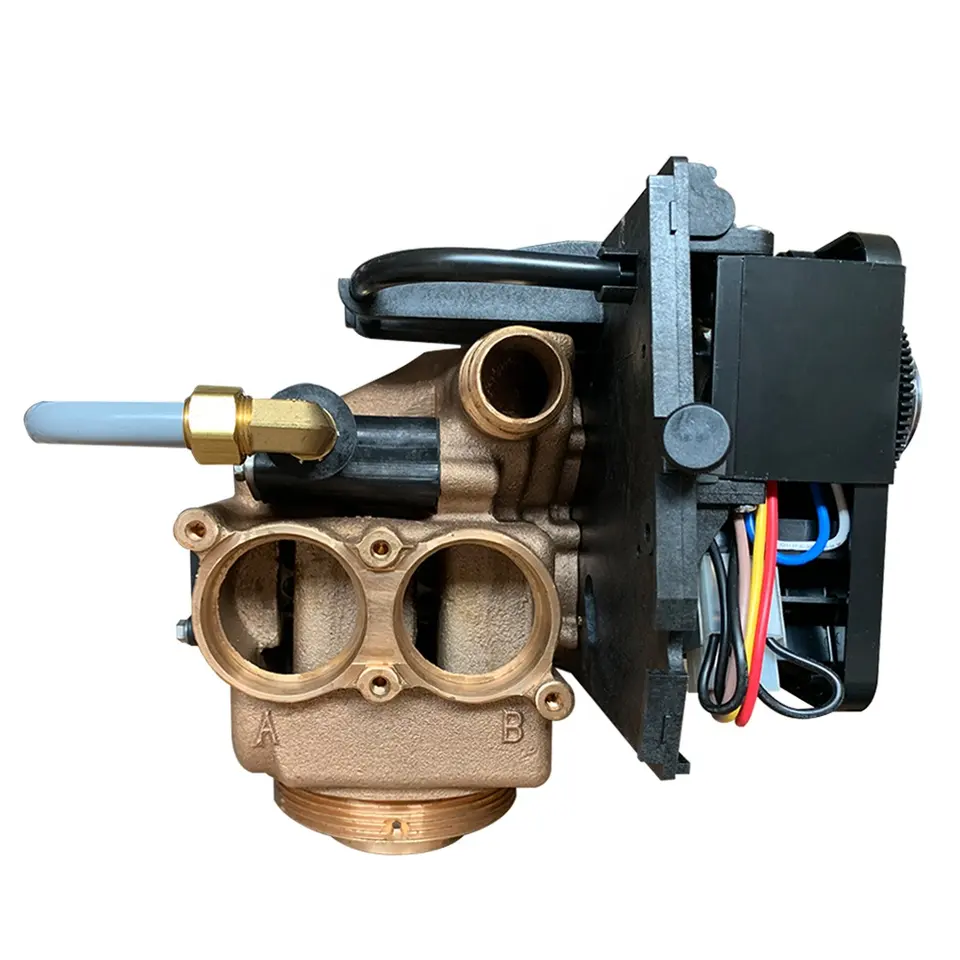

Water softener control valves are an integral part of any water softening system. They play a pivotal role in managing the flow of water through the system, ensuring that the water is adequately softened and that the system operates efficiently. Understanding the functionality of these control valves can help homeowners and businesses maintain their water softening systems more effectively, ensuring a consistent supply of softened water.

Water softeners are designed to remove minerals such as calcium and magnesium from hard water. These minerals can cause a variety of problems, including scale buildup in pipes and appliances, reduced effectiveness of soaps and detergents, and potential health issues. The water softener control valve is the component that directs the flow of water through the system, ensuring that it passes through the resin bed where the hard water minerals are removed.

The control valve is essentially the brain of the water softening system. It determines when the system needs to regenerate, based on the amount of water that has been used or the amount of hardness that has been removed. During regeneration, the control valve directs water to flow through the resin bed in a reverse direction, flushing out the accumulated minerals and recharging the resin with sodium ions. This process is crucial for maintaining the effectiveness of the water softening system.

The control valve also manages the flow rate of the water through the system. It ensures that the water flows at a rate that allows for optimal contact time with the resin, which is necessary for the ion exchange process to occur. If the water flows too quickly, it may not spend enough time in contact with the resin, resulting in less effective softening. Conversely, if the water flows too slowly, it can cause unnecessary strain on the system and reduce its overall efficiency.

There are different types of control valves available, each with its own set of features and benefits. Some valves are manually operated, requiring the user to manually initiate the regeneration process. Others are automatic, using timers or sensors to determine when regeneration is needed. There are also demand-initiated regeneration valves, which regenerate based on the actual water usage, making them more efficient and cost-effective.

The choice of control valve can significantly impact the performance and efficiency of a water softening system. Therefore, it’s important to consider factors such as water hardness, water usage, and the specific requirements of the system when choosing a control valve. Regular maintenance of the control valve is also crucial, as it can help prevent malfunctions and prolong the lifespan of the water softening system.

In conclusion, the water softener control valve is a critical component that governs the operation of the water softening system. It manages the flow of water, initiates the regeneration process, and ensures the system operates at peak efficiency. Understanding the functionality of the control valve can help in making informed decisions about the selection and maintenance of a water softening system, ultimately leading to improved water quality and system longevity.

Maintenance Tips for Water Softener Control Valves

Water softener control valves are integral components of water softening systems. They regulate the flow of water through the system, controlling the regeneration cycle, which is crucial for the softening process. Despite their importance, these valves are often overlooked when it comes to maintenance. However, regular upkeep can significantly extend the lifespan of these valves and the overall efficiency of the water softening system.

Firstly, it is essential to understand the function of the control valve. It directs the flow of water into the resin tank during the service cycle and reverses the flow for backwashing during the regeneration cycle. The valve also controls the brine draw and slow rinse cycles. Understanding these functions can help identify potential issues and ensure the valve is working correctly.

One of the most common problems with water softener control valves is blockages. These can occur due to sediment build-up or the presence of iron in the water. Regular inspection of the valve can help identify any blockages early on. If a blockage is found, it can usually be cleared by flushing the system with a solution designed to remove iron and sediment.

| Model: Automatic Softener Valve | ASE2 -LCD/LED | |

| Refilling type | refill before regeneration | refill after regeneration |

| Working Position | Service->Refill the softener water->Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Service | Service->Back Wash->Upflow Brine and slow rinse-> Fast rinse-> Refill the softener water->Service |

| Automatic type | Automatic type | |

| Meter Delay | Meter Delay | |

| Regeneration mode | Intelligent Meter Delay | Meter immediate |

| Timer by day : 0-99 days | Intelligent Meter Delay | |

| Timer by hours: 0-99 hours | Intelligent Meter Immediate | |

| Timer by day : 0-99 days | ||

| Timer by hours: 0-99 hours | ||

| Inlet | 1/2” 3/4” 1” | |

| Outlet | 1/2” 3/4” 1” | |

| Drain | 1/2” | |

| Base | 2-1/2” | |

| Riser pipe | 1.05” OD | |

| Water Capacity | 2m3/h | |

| Working Pressure | 0.15-0.6Mpa | |

| Working Temperature | 5-50°C | |

| Power Supply | AC100-240 / 50-60Hz / DC12V-1.5A | |

Another common issue is wear and tear on the valve’s seals and spacers. Over time, these components can wear down, leading to leaks or a reduction in the system’s efficiency. It’s recommended to replace these parts every five years or so, depending on the hardness of your water and the frequency of regeneration cycles.

In addition to these specific issues, general cleaning and maintenance of the control valve are also crucial. This includes regularly checking for leaks, ensuring the valve is securely fastened, and cleaning the valve with a mild detergent. It’s also a good idea to lubricate the moving parts of the valve periodically to ensure smooth operation.

While these maintenance tasks can be performed by the homeowner, it’s often beneficial to enlist the help of a professional. A trained technician can thoroughly inspect the control valve, identify any potential issues, and perform necessary repairs or replacements. They can also provide advice on how to maintain the valve and the overall system to ensure optimal performance.

It’s also worth noting that not all water softener control valves are created equal. Some models are more durable and easier to maintain than others. When choosing a water softener system, it’s worth considering the type of control valve it uses. Look for models with high-quality valves that are known for their durability and ease of maintenance.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| ASDU2 | automatic softener valve | 2 | O | O | O | O |

| ASDU2-H | automatic softener valve | 2 | O | O | X | X |

| ASDU4 | automatic softener valve | 4 | O | O | O | O |

| ASDU4-L | automatic softener valve | 4 | O | O | O | O |

In conclusion, regular maintenance of water softener control valves is essential for the longevity and efficiency of your water softening system. This includes regular inspections for blockages and wear and tear, cleaning, and occasional replacement of parts. While these tasks can be performed by the homeowner, professional assistance can be invaluable. By taking care of your control valve, you can ensure that your water softening system continues to provide soft, clean water for many years to come.