“Strong, durable, and reliable PVC for all your electrical conduit needs.”

Table of Contents

Pros and Cons of Using Schedule 40 PVC for Electrical Conduit

When it comes to choosing the right material for electrical conduit, PVC (polyvinyl chloride) is a popular choice due to its durability, affordability, and ease of installation. One common type of PVC used for electrical conduit is Schedule 40 PVC. This type of PVC is known for its thick walls and high pressure rating, making it suitable for a variety of applications. However, like any material, Schedule 40 PVC has its pros and cons that should be considered before making a decision.

One of the main advantages of using Schedule 40 PVC for electrical conduit is its durability. Schedule 40 PVC is designed to withstand high pressure and impact, making it a reliable choice for protecting electrical wires from damage. Additionally, Schedule 40 PVC is resistant to corrosion, moisture, and chemicals, making it ideal for outdoor and underground installations where exposure to harsh elements is a concern.

Another benefit of using Schedule 40 PVC for electrical conduit is its affordability. PVC is a cost-effective material compared to metal conduits such as steel or aluminum. This can result in significant cost savings for projects that require a large amount of conduit. Additionally, PVC is lightweight and easy to transport, reducing labor costs associated with handling and installation.

In terms of installation, Schedule 40 PVC is known for its ease of use. PVC conduits can be easily cut, assembled, and glued together using solvent cement, eliminating the need for specialized tools or equipment. This makes PVC conduits a popular choice for DIY enthusiasts and contractors alike. Additionally, PVC conduits can be easily bent and shaped to fit around obstacles, making them versatile and adaptable to various installation scenarios.

Despite its many advantages, there are some drawbacks to using Schedule 40 PVC for electrical conduit. One of the main concerns with PVC conduits is their limited temperature range. PVC becomes brittle at low temperatures and can soften and deform at high temperatures, potentially compromising the integrity of the conduit. This can be a significant issue in extreme weather conditions or in applications where the conduit is exposed to high temperatures.

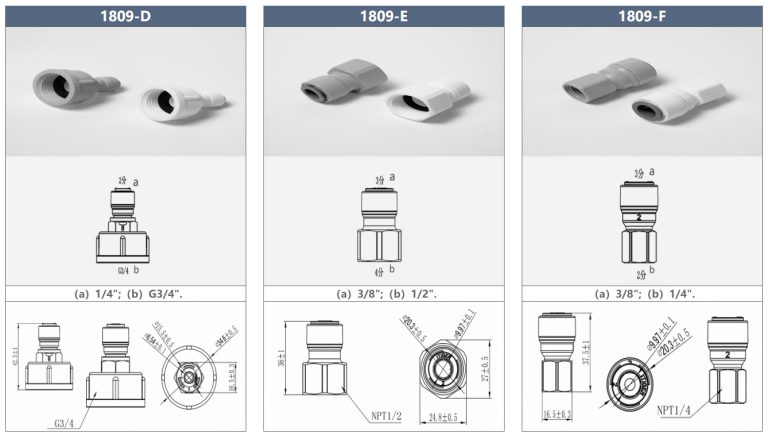

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/35 |

Another drawback of using Schedule 40 PVC for electrical conduit is its limited impact resistance. While PVC is durable and resistant to impact, it is not as strong as metal conduits and can be prone to cracking or breaking under heavy loads. This can be a concern in areas where the conduit is exposed to heavy machinery or vehicles.

In conclusion, Schedule 40 PVC is a popular choice for electrical conduit due to its durability, affordability, and ease of installation. However, it is important to weigh the pros and cons of using PVC conduits before making a decision. While PVC conduits offer many benefits, such as corrosion resistance and cost savings, they also have limitations, such as temperature sensitivity and limited impact resistance. By carefully considering these factors, you can make an informed decision on whether Schedule 40 PVC is the right choice for your electrical conduit needs.

Benefits of Using Schedule 80 PVC for Electrical Conduit

When it comes to choosing the right material for electrical conduit, PVC (polyvinyl chloride) is a popular choice due to its durability, affordability, and ease of installation. PVC conduit is available in different schedules, with Schedule 40 and Schedule 80 being the most common options. While both types of PVC conduit are suitable for electrical applications, Schedule 80 PVC offers several benefits that make it a preferred choice for many electricians and contractors.

One of the main advantages of using Schedule 80 PVC for electrical conduit is its increased wall thickness. Schedule 80 PVC conduit is designed to withstand higher pressure and impact compared to Schedule 40 PVC, making it more durable and resistant to damage. This extra strength and durability make Schedule 80 PVC conduit ideal for outdoor and underground installations where the conduit may be exposed to harsh weather conditions or physical stress.

In addition to its superior strength, Schedule 80 PVC conduit is also more resistant to heat and fire. PVC has a high ignition temperature and is self-extinguishing, which means that it will not support combustion once the flame source is removed. This fire-resistant property makes Schedule 80 PVC conduit a safe choice for electrical installations in buildings where fire safety is a concern.

Another benefit of using Schedule 80 PVC for electrical conduit is its chemical resistance. PVC is inherently resistant to a wide range of chemicals, including acids, alkalis, and solvents, making it suitable for use in industrial environments where exposure to corrosive substances is a possibility. Schedule 80 PVC conduit is also resistant to UV radiation, which means that it will not degrade or become brittle when exposed to sunlight over time.

Furthermore, Schedule 80 PVC conduit is easy to work with and install, thanks to its lightweight and flexible nature. PVC conduit can be easily cut, bent, and joined using solvent cement, making it a versatile option for a variety of electrical applications. The smooth interior surface of PVC conduit also reduces friction and allows for easy pulling of wires, saving time and effort during installation.

In terms of cost, Schedule 80 PVC conduit is an affordable option compared to other materials such as metal or fiberglass. PVC conduit is readily available at hardware stores and electrical supply shops, and its low cost makes it a budget-friendly choice for electrical projects of any size. Additionally, the long lifespan of PVC conduit means that it will require minimal maintenance and replacement over time, further reducing overall costs.

In conclusion, Schedule 80 PVC conduit offers a range of benefits that make it a practical and cost-effective choice for electrical installations. Its superior strength, fire resistance, chemical resistance, and ease of installation make it a versatile option for a variety of applications, from residential wiring to industrial projects. Whether you are a professional electrician or a DIY enthusiast, Schedule 80 PVC conduit is a reliable and durable solution for all your electrical conduit needs.