“PVC: Insulating against electrical conductivity.”

Table of Contents

Potential Risks of Using PVC in Electrical Wiring

Polyvinyl chloride (PVC) is a commonly used material in the construction industry due to its durability, flexibility, and cost-effectiveness. However, when it comes to electrical wiring, there are potential risks associated with using PVC. One of the main concerns is whether PVC can conduct electricity.

PVC is a non-conductive material, meaning it does not conduct electricity. This property makes it a popular choice for insulating electrical wires, as it helps prevent electrical shocks and short circuits. However, despite its non-conductive nature, there are still risks involved in using PVC in electrical wiring.

One of the main risks of using PVC in electrical wiring is its flammability. PVC is a thermoplastic material, which means it can melt and burn when exposed to high temperatures. In the event of a fire, PVC can release toxic fumes and gases, posing a serious health hazard to anyone nearby. This is why it is important to use PVC that is specifically designed for electrical applications, as it is formulated to be more fire-resistant.

Another risk of using PVC in electrical wiring is its susceptibility to degradation over time. Exposure to sunlight, heat, and chemicals can cause PVC to become brittle and crack, compromising its insulating properties. This can lead to exposed wires, increasing the risk of electrical hazards such as short circuits and fires. Regular maintenance and inspection of PVC-insulated wires are essential to ensure their safety and reliability.

In addition to its flammability and degradation risks, PVC also poses environmental concerns. PVC is a synthetic plastic made from petroleum, a non-renewable resource. The production and disposal of PVC can have negative impacts on the environment, including air and water pollution. As awareness of environmental issues grows, there is a push towards using more sustainable materials in construction, including electrical wiring.

Despite these risks, PVC remains a popular choice for electrical wiring due to its affordability and ease of installation. However, there are alternatives to PVC that offer similar benefits without the same risks. For example, thermoset materials such as cross-linked polyethylene (XLPE) and ethylene propylene rubber (EPR) are non-conductive, flame-retardant, and more resistant to degradation than PVC. These materials are also more environmentally friendly, making them a preferred choice for some applications.

In conclusion, while PVC is a non-conductive material that is commonly used in electrical wiring, there are potential risks associated with its use. Its flammability, susceptibility to degradation, and environmental impact are important factors to consider when choosing materials for electrical installations. By understanding these risks and exploring alternative materials, it is possible to mitigate the potential dangers of using PVC in electrical wiring.

How to Safely Ground PVC to Prevent Electrical Conductivity

Polyvinyl chloride (PVC) is a widely used material in various industries due to its versatility and durability. However, one common concern with PVC is its ability to conduct electricity. PVC is an insulating material, meaning it does not conduct electricity easily. However, under certain conditions, PVC can become conductive, posing a potential safety hazard. In this article, we will explore how to safely ground PVC to prevent electrical conductivity.

When PVC comes into contact with moisture or certain chemicals, it can develop a static charge that may lead to electrical conductivity. This is particularly concerning in industrial settings where PVC pipes or equipment are used to transport liquids or gases. To prevent the risk of electrical conductivity, it is essential to properly ground PVC components.

Grounding is the process of connecting an electrical conductor to the earth to prevent the buildup of static electricity and ensure the safe dissipation of any electrical charges. In the case of PVC, grounding can help to mitigate the risk of electrical conductivity by providing a path for the current to flow safely to the ground.

There are several methods for grounding PVC components, depending on the specific application and environment. One common approach is to use grounding straps or wires to connect PVC pipes or equipment to a grounding rod or other suitable grounding point. These straps or wires should be securely attached to the PVC component and the grounding point to ensure a reliable connection.

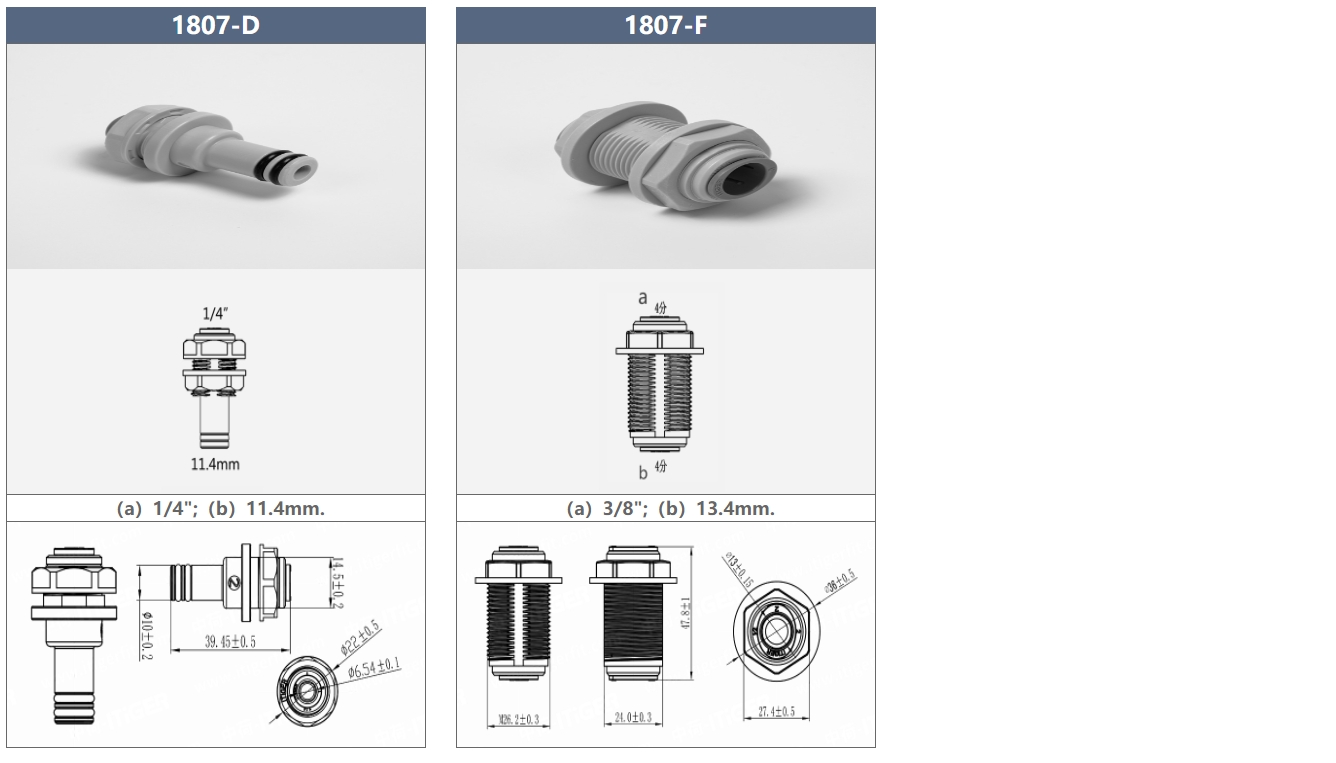

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/23 |

Another effective method for grounding PVC is to use conductive coatings or additives. These coatings or additives can be applied to the surface of the PVC material to enhance its conductivity and facilitate the safe dissipation of electrical charges. Conductive coatings are often used in industrial applications where PVC components are exposed to high levels of moisture or chemicals that may increase the risk of electrical conductivity.

In addition to grounding PVC components, it is important to regularly inspect and maintain the grounding system to ensure its effectiveness. This includes checking the integrity of grounding straps or wires, monitoring the condition of conductive coatings, and verifying the continuity of the grounding connection. Any signs of damage or deterioration should be promptly addressed to prevent the risk of electrical conductivity.

In conclusion, while PVC is generally considered an insulating material, it can become conductive under certain conditions. To prevent the risk of electrical conductivity, it is essential to properly ground PVC components using grounding straps, conductive coatings, or other suitable methods. By implementing effective grounding practices and conducting regular maintenance, you can ensure the safe operation of PVC equipment and prevent potential safety hazards. Remember, safety should always be the top priority when working with PVC and other electrical materials.