How to Properly Maintain and Operate WS1 clack valve Manual

The WS1 clack valve Manual is an essential component of water softening systems, providing control over the regeneration process and ensuring the efficient operation of the system. Proper maintenance and operation of the WS1 clack valve Manual are crucial to ensure the longevity and effectiveness of your water softening system.

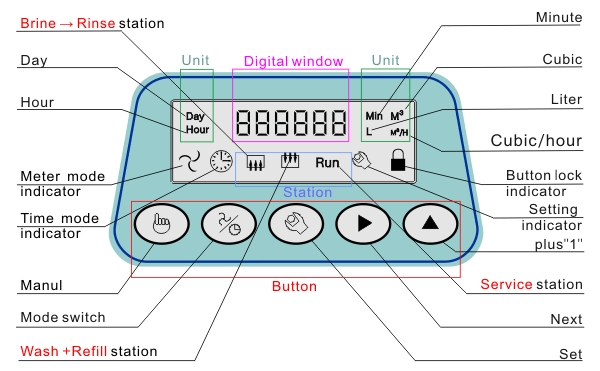

To begin, it is important to familiarize yourself with the WS1 clack valve Manual and its various components. The manual provides detailed instructions on how to program and operate the valve, as well as information on troubleshooting common issues. It is recommended to keep the manual in a safe and easily accessible location for reference.

| Model:\u00a0Automatic\u00a0Softener\u00a0Valve | ASE2 -LCD/LED\u00a0\u00a0 \u00a0 \u00a0 \u00a0 | |

| Refilling type | \u00a0\u00a0\u00a0\u00a0refill before regeneration\u00a0\u00a0 | refill after regeneration |

| Working Position\u00a0 | Service->Refill the softener water->Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Service | Service->Back Wash->Upflow Brine and slow rinse-> Fast rinse-> Refill the softener\u00a0\u00a0water->Service |

| \u3000 | Automatic type\u00a0 | Automatic type\u00a0 |

| \u3000 | Meter Delay\u00a0 | Meter Delay\u00a0 |

| Regeneration mode | Intelligent Meter Delay | Meter immediate |

| \u3000 | Timer by day : \u00a00-99\u00a0days\u00a0 | Intelligent Meter Delay |

| \u3000 | Timer by hours: 0-99 hours\u00a0 | Intelligent Meter Immediate |

| \u3000 | \u3000 | Timer by day : \u00a00-99\u00a0days\u00a0 |

| \u3000 | \u3000 | Timer by hours: 0-99 hours |

| Inlet | 1/2” \u00a03/4” \u00a01”\u00a0 | |

| Outlet | 1/2” \u00a03/4” \u00a01”\u00a0 | |

| Drain | 1/2” \u00a0 | |

| Base | 2-1/2” | |

| Riser pipe | 1.05” OD | |

| Water Capacity | 2m3/h | |

| Working Pressure | 0.15-0.6Mpa | |

| Working Temperature | 5-50\u00b0C | |

| Power Supply | AC100-240 / 50-60Hz \u00a0 \u00a0 / \u00a0 \u00a0 \u00a0 DC12V-1.5A \u00a0 | |

Regular maintenance of the WS1 clack valve Manual is essential to prevent malfunctions and ensure optimal performance. One of the most important maintenance tasks is to regularly check and clean the valve and brine tank. Over time, debris and mineral buildup can accumulate in these areas, leading to clogs and reduced efficiency. It is recommended to clean the valve and brine tank at least once a year, or more frequently if you notice any issues.

In addition to cleaning, it is important to regularly check the settings and programming of the WS1 clack valve Manual. Ensure that the valve is set to the correct time and date, as well as the appropriate regeneration cycle. It is also important to monitor the salt levels in the brine tank and replenish as needed to ensure proper operation.

When operating the WS1 clack valve Manual, it is important to follow the manufacturer’s instructions carefully. Avoid making any adjustments or changes to the settings without consulting the manual, as this can lead to malfunctions and damage to the system. It is also important to monitor the system regularly for any signs of leaks or unusual noises, as these can indicate a problem with the valve.

In the event of a malfunction or issue with the WS1 clack valve Manual, it is important to troubleshoot the problem promptly. Refer to the manual for guidance on common issues and solutions, and contact a professional if you are unable to resolve the problem on your own. Ignoring issues with the valve can lead to more serious problems and costly repairs down the line.

In conclusion, proper maintenance and operation of the WS1 clack valve Manual are essential to ensure the longevity and effectiveness of your water softening system. By following the manufacturer’s instructions, regularly cleaning and checking the valve, and promptly addressing any issues that arise, you can ensure that your system operates efficiently and effectively for years to come. Remember to keep the manual handy for reference and consult a professional if you encounter any problems that you are unable to resolve on your own.