“Y-shaped plastic tube: Versatile and efficient for all your piping needs.”

Y-Shaped Plastic Tubes: Uses and Benefits

Y-shaped plastic tubes are a versatile and practical tool used in a variety of industries for a wide range of applications. These tubes are designed with a unique Y-shaped configuration, allowing for multiple pathways for the flow of liquids, gases, or other substances. The design of these tubes makes them ideal for situations where branching or splitting of a fluid stream is required.

One of the primary uses of Y-shaped plastic tubes is in the medical field. These tubes are commonly used in medical devices such as catheters and IV sets, where the branching design allows for the simultaneous delivery of multiple fluids or medications. The Y-shaped configuration also enables healthcare professionals to easily monitor and control the flow of fluids to the patient, making these tubes an essential component in medical procedures.

In addition to their use in the medical field, Y-shaped plastic tubes are also utilized in laboratory settings for various research and testing purposes. These tubes are often used in chromatography, a technique used to separate and analyze complex mixtures. The Y-shaped design of the tubes allows for the separation of different components of a mixture, making them an essential tool for scientists and researchers working in analytical chemistry.

Another common application of Y-shaped plastic tubes is in industrial processes, where they are used for fluid distribution and control. These tubes are often used in manufacturing plants and chemical processing facilities to transport liquids or gases to different parts of the production line. The branching design of the tubes allows for efficient distribution of fluids, helping to streamline the manufacturing process and improve overall efficiency.

Y-shaped plastic tubes are also used in the automotive industry for various applications, such as in fuel systems and cooling systems. The branching design of these tubes allows for the efficient flow of fluids to different parts of the vehicle, helping to ensure optimal performance and reliability. These tubes are also used in the construction industry for plumbing and irrigation systems, where the branching design allows for the distribution of water to multiple outlets.

One of the key benefits of Y-shaped plastic tubes is their durability and resistance to corrosion. These tubes are typically made from high-quality plastics such as PVC or polyethylene, which are known for their strength and longevity. This makes Y-shaped plastic tubes a cost-effective and reliable option for a wide range of applications, as they can withstand harsh environmental conditions and chemical exposure without degrading or deteriorating.

In conclusion, Y-shaped plastic tubes are a versatile and practical tool that finds applications in various industries, including healthcare, research, manufacturing, automotive, and construction. The unique Y-shaped configuration of these tubes allows for efficient branching and splitting of fluid streams, making them an essential component in many processes. With their durability, resistance to corrosion, and cost-effectiveness, Y-shaped plastic tubes are a valuable asset for any industry looking to improve fluid distribution and control.

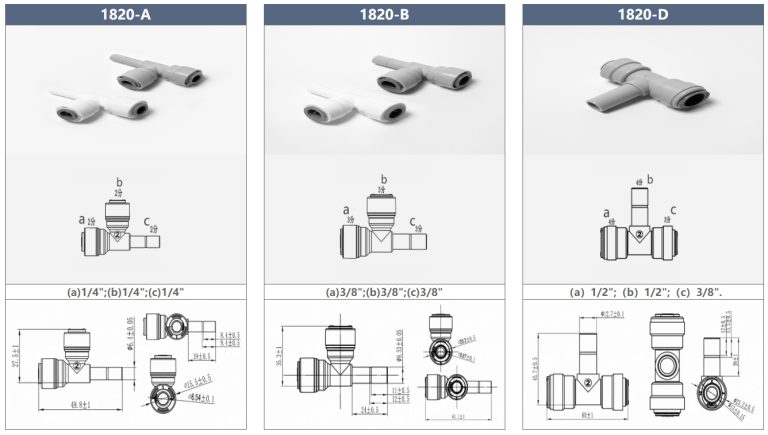

| Model | Stem (a) |

Stem (b) |

Tube (c) |

| 1800-A | 1/4 | 1/4 | – |

| 1800-B | 1/4 | 1/4 | Short |

| 1800-D | 1/2 | 1/2 | Short |