Advantages of Using an Ideal Flow Sensor in Industrial Applications

Flow sensors are essential components in industrial applications where monitoring and controlling the flow of liquids or gases is crucial. An ideal flow sensor is one that provides accurate and reliable measurements while being cost-effective and easy to install. In this article, we will discuss the advantages of using an ideal flow sensor in industrial applications.

One of the main advantages of using an ideal flow sensor is its accuracy. Accurate flow measurements are essential in industries such as pharmaceuticals, food and beverage, and chemical processing, where even small variations in flow rates can have a significant impact on the quality of the final product. An ideal flow sensor ensures that the measurements are precise, allowing for better control over the production process.

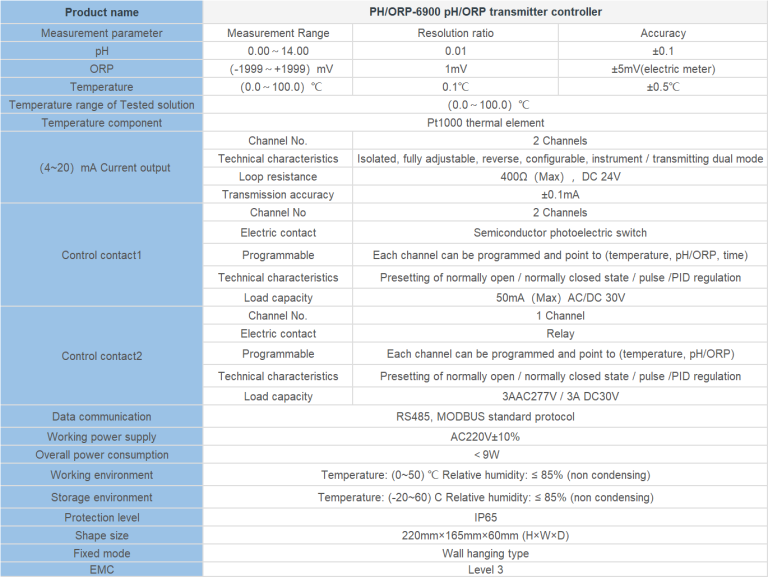

| pH/ORP-3500 series pH/ORP Online Meter | |||

| pH | ORP | Temp. | |

| Measurement range | 0.00~14.00 | (-2000~+2000)mV | (0.0~99.9)℃(Temp. Compensation :NTC10K) |

| Resolution | 0.01 | 1mV | 0.1℃ |

| Accuracy | ±0.1 | ±5mV(electronic unit) | ±0.5℃ |

| Buffer Solution | 9.18;6.86;4.01;10.00;7.00;4.00 | ||

| Medium Temp. | (0~50)℃(with 25℃ as standard )manual / automatic temp.compensation for selection | ||

| Analog Output | Isolated one Channel(4~20)mA,Instrument / Transmitter for selection | ||

| Control Output | Double relay output(ON/OFF) | ||

| Consumption | <3W | ||

| Working Environment | Working temp. (0~50)℃;Relative humidity≤85%RH(none condensation) | ||

| Storage Environment | Temp. (-20~60)℃; Relative humidity≤85%RH(none condensation) | ||

| Dimension | 48mm×96mm×80mm (H×W×D) | ||

| Hole Size | 44mm×92mm (H×W) | ||

| Installation | Panel mounted ,fast installation | ||

Another advantage of using an ideal flow sensor is its reliability. In industrial settings, where downtime can be costly, having a flow sensor that is reliable and consistent is crucial. An ideal flow sensor is designed to withstand harsh conditions and provide accurate measurements over an extended period of time, reducing the risk of equipment failure and production delays.

Cost-effectiveness is also a key advantage of using an ideal flow sensor. While there may be cheaper options available, investing in a high-quality flow sensor can save money in the long run by reducing maintenance costs and minimizing the risk of production errors. An ideal flow sensor is designed to be durable and long-lasting, making it a cost-effective solution for industrial applications.

Ease of installation is another advantage of using an ideal flow sensor. Installing a flow sensor can be a complex and time-consuming process, especially in industrial settings where space is limited and access to equipment is restricted. An ideal flow sensor is designed to be easy to install, with simple mounting options and user-friendly interfaces that make setup quick and efficient.

| Model | NTU-1800 Online Turbidity Tester |

| Range | 0-10/100/4000NTU or as required |

| Display | LCD |

| Unit | NTU |

| DPI | 0.01 |

| Accuracy | ±5% FS |

| Repeatability | ±1% |

| Power | ≤3W |

| Power Supply | AC 85V-265V±10% 50/60Hz or |

| DC 9~36V/0.5A | |

| Working Environment | Ambient temperature:0~50℃; |

| Relative humidity≤85% | |

| Dimensions | 160*80*135mm(Hanging) or 96*96mm(Embeded) |

| Communication | 4~20mA and RS-485 communication (Modbus RTU) |

| Switched output | Three-way relay,capacity 250VAC/5A |

Overall, using an ideal flow sensor in industrial applications offers numerous advantages, including accuracy, reliability, cost-effectiveness, ease of installation, and versatility. By investing in a high-quality flow sensor, industrial companies can improve their production processes, reduce downtime, and ensure the quality of their final products. Whether it’s monitoring the flow of chemicals in a processing plant or controlling the flow of water in a cooling system, an ideal flow sensor is an essential tool for any industrial application.