Table of Contents

Benefits of Using Pentair Ball Valves in Industrial Applications

Pentair ball valves are a popular choice for industrial applications due to their durability, reliability, and efficiency. These valves are designed to control the flow of liquids or gases in a system by using a spherical ball with a hole in the middle to regulate the flow. The ball valve is opened and closed by turning a handle attached to the ball, allowing for precise control over the flow rate.

One of the key benefits of using Pentair ball valves in industrial applications is their durability. These valves are made from high-quality materials such as stainless steel, brass, or PVC, which are resistant to corrosion and wear. This means that Pentair ball valves can withstand harsh operating conditions and last for a long time without needing frequent maintenance or replacement.

In addition to their durability, Pentair ball valves are also known for their reliability. These valves are designed to provide a tight seal when closed, preventing leaks and ensuring that the system operates smoothly. This reliability is crucial in industrial applications where even a small leak can lead to costly downtime and repairs. With Pentair ball valves, you can trust that your system will operate efficiently and effectively without any unexpected interruptions.

Another benefit of using Pentair ball valves in industrial applications is their efficiency. These valves are designed to provide precise control over the flow rate, allowing operators to adjust the flow as needed to meet the requirements of the system. This level of control can help improve the overall efficiency of the system, reducing waste and saving energy. In addition, Pentair ball valves are easy to operate, making it simple for operators to adjust the flow rate quickly and accurately.

Furthermore, Pentair ball valves are versatile and can be used in a wide range of industrial applications. Whether you need to control the flow of water, oil, gas, or chemicals, Pentair ball valves can handle the job. These valves come in a variety of sizes and configurations to suit different system requirements, making them a flexible and adaptable choice for industrial applications.

Overall, Pentair ball valves offer a range of benefits that make them an excellent choice for industrial applications. From their durability and reliability to their efficiency and versatility, these valves are designed to provide precise control over the flow of liquids or gases in a system. If you are looking for a reliable and efficient valve solution for your industrial application, consider using Pentair ball valves. With their high-quality construction and performance, you can trust that these valves will meet your needs and help your system operate smoothly and efficiently.

How to Properly Maintain and Service Pentair Ball Valves

Pentair ball valves are essential components in many industrial and commercial applications, providing reliable control of fluid flow. To ensure the longevity and efficiency of these valves, proper maintenance and servicing are crucial. In this article, we will discuss the steps and best practices for maintaining and servicing Pentair ball valves.

Regular inspection is the first step in maintaining Pentair ball valves. Inspect the valve for any signs of wear, corrosion, or leaks. Check the valve’s operation by opening and closing it to ensure smooth movement. If there are any abnormalities or issues, it is important to address them promptly to prevent further damage.

Cleaning the valve is another important aspect of maintenance. Dirt, debris, and other contaminants can build up in the valve, affecting its performance. Use a mild detergent and water to clean the valve thoroughly, making sure to remove any residue or buildup. Inspect the seals and gaskets for any signs of wear or damage, as these components are critical for the proper functioning of the valve.

Lubrication is essential for ensuring smooth operation of Pentair ball valves. Apply a small amount of lubricant to the valve stem and other moving parts to reduce friction and wear. Be sure to use a lubricant that is compatible with the materials used in the valve to prevent damage.

In addition to regular maintenance, servicing Pentair ball valves is necessary to address any issues or malfunctions. If the valve is leaking, not operating properly, or showing signs of wear, it may be time to service the valve. This can involve replacing worn seals or gaskets, repairing damaged components, or even replacing the entire valve if necessary.

When servicing Pentair ball valves, it is important to follow the manufacturer’s guidelines and recommendations. Use the appropriate tools and equipment to disassemble the valve carefully, taking note of the position of each component. Clean and inspect all parts thoroughly, replacing any damaged or worn components as needed. Reassemble the valve carefully, ensuring that all parts are properly aligned and tightened.

After servicing the valve, it is important to test its operation to ensure that it is functioning correctly. Open and close the valve several times to check for smooth movement and proper sealing. Check for any leaks or abnormalities and address them promptly.

| Model:\u00a0Automatic\u00a0Softener\u00a0Valve | ASE2 -LCD/LED\u00a0\u00a0 \u00a0 \u00a0 \u00a0 | |

| Refilling type | \u00a0\u00a0\u00a0\u00a0refill before regeneration\u00a0\u00a0 | refill after regeneration |

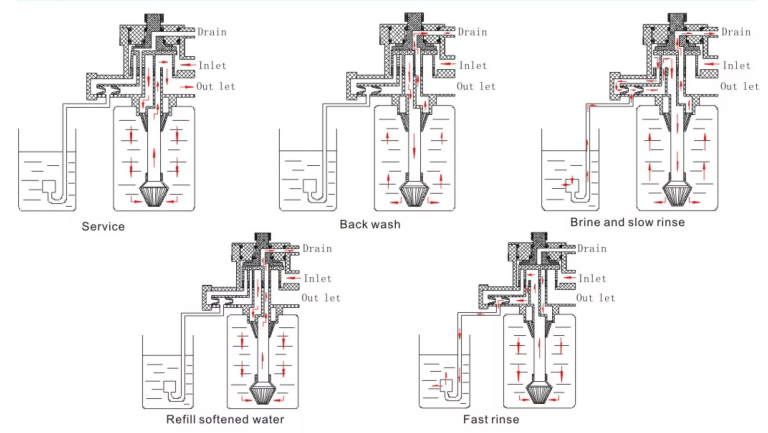

| Working Position\u00a0 | Service->Refill the softener water->Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Service | Service->Back Wash->Upflow Brine and slow rinse-> Fast rinse-> Refill the softener\u00a0\u00a0water->Service |

| \u3000 | Automatic type\u00a0 | Automatic type\u00a0 |

| \u3000 | Meter Delay\u00a0 | Meter Delay\u00a0 |

| Regeneration mode | Intelligent Meter Delay | Meter immediate |

| \u3000 | Timer by day : \u00a00-99\u00a0days\u00a0 | Intelligent Meter Delay |

| \u3000 | Timer by hours: 0-99 hours\u00a0 | Intelligent Meter Immediate |

| \u3000 | \u3000 | Timer by day : \u00a00-99\u00a0days\u00a0 |

| \u3000 | \u3000 | Timer by hours: 0-99 hours |

| Inlet | 1/2” \u00a03/4” \u00a01”\u00a0 | |

| Outlet | 1/2” \u00a03/4” \u00a01”\u00a0 | |

| Drain | 1/2” \u00a0 | |

| Base | 2-1/2” | |

| Riser pipe | 1.05” OD | |

| Water Capacity | 2m3/h | |

| Working Pressure | 0.15-0.6Mpa | |

| Working Temperature | 5-50\u00b0C | |

| Power Supply | AC100-240 / 50-60Hz \u00a0 \u00a0 / \u00a0 \u00a0 \u00a0 DC12V-1.5A \u00a0 | |

Proper maintenance and servicing of Pentair ball valves are essential for ensuring their longevity and efficiency. By following these steps and best practices, you can keep your valves in optimal condition and prevent costly repairs or replacements. Remember to inspect, clean, lubricate, and service your valves regularly to keep them operating smoothly and reliably.