Importance of conductivity meter Calibration According to IP Standards

Conductivity meters are essential tools used in various industries to measure the ability of a solution to conduct electricity. These meters are widely used in laboratories, water treatment plants, and manufacturing facilities to ensure the quality and consistency of products. To maintain the accuracy and reliability of conductivity meters, regular calibration is necessary. Calibration is the process of adjusting the meter to ensure that it provides accurate and precise measurements. In the case of conductivity meters, calibration is typically done using standards set by organizations such as the Institute of Petroleum (IP).

The IP standards are widely recognized in the industry for their rigorous testing procedures and accuracy. conductivity meter calibration as per IP standards ensures that the meter is calibrated to a known standard, allowing for consistent and reliable measurements. By following IP standards, organizations can ensure that their conductivity meters are operating within acceptable limits and producing accurate results.

One of the key benefits of conducting conductivity meter calibration as per IP standards is the assurance of accuracy. IP standards provide a set of guidelines and procedures for calibrating conductivity meters, ensuring that the measurements obtained are reliable and consistent. This is particularly important in industries where precise measurements are critical, such as pharmaceutical manufacturing or water treatment.

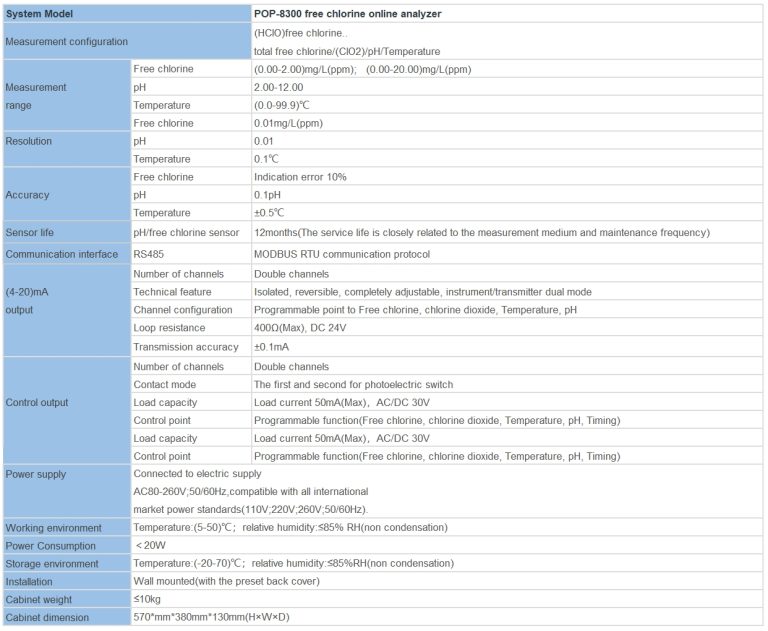

| FCT-8350 Flow Transmitter | |

| Measurement range | Instantaneous flow:(0~2000)m3/h;Accumulated flow:(0~99999999)m3 |

| Flow rate | (0~5)m/s |

| Applicable pipe diameter | DN 25~DN 1000 for selection |

| Resolution | 0.001 m3/h |

| Renew interval | 1S |

| Accuracy | 2.0 level |

| Repeatability | \u00b10.5% |

| Probe input | Range :0.5Hz~2KHz;Power supply:DC 12V(instrument supply) |

| Analog output | (4~20)mA,Instrument/transmitter for selection; |

| Control output | Semi-conductor photo electronic relay,Load current 50mA(max),AC/DC 30V |

| Control mode | Instantaneous flow high/low limit alarm, flow variable frequency conversion |

| Working power | DC24V |

| Power consumption: | <3.0W |

| Cable length | 5m as standard ; or(1~500)m for selection |

| Working environment | Temp.:(0~50)\u2103;relative humidity\u226485%RH(non condensation) |

| Storage environment | Temp.:(-20~60)\u2103; relative humidity:\u226485%RH(non condensation) |

| Protection level | IP65(with back cover) |

| Dimension | 96 mm\u00d796 mm\u00d794mm (H\u00d7W\u00d7D) |

| Hole size | 91mm\u00d791mm(H\u00d7W) |

| Installation | Panel mounted,fast installation |

Furthermore, calibration as per IP standards can help organizations identify and address potential issues with their conductivity meters. By regularly calibrating meters, organizations can detect any drift or inaccuracies in measurements and take corrective action before they impact product quality or compliance.

To calibrate a conductivity meter as per IP standards, organizations must follow a set of procedures outlined by the IP. These procedures typically involve using standard solutions with known conductivity values to adjust the meter and ensure accurate measurements. The calibration process may also involve verifying the meter’s performance against a set of criteria specified by the IP.

It is important for organizations to conduct conductivity meter calibration regularly to ensure the accuracy and reliability of measurements. By following IP standards, organizations can ensure that their conductivity meters are operating within acceptable limits and producing accurate results. Calibration as per IP standards also helps organizations comply with regulatory requirements and identify potential issues with their meters.

In conclusion, conductivity meter calibration as per IP standards is essential for ensuring the accuracy and reliability of measurements in various industries. By following IP standards, organizations can maintain the quality and consistency of products, comply with regulatory requirements, and identify and address potential issues with their conductivity meters. conductivity meter calibration as per IP standards is a best practice that can help organizations achieve optimal performance and reliability from their meters.