Table of Contents

Responsibilities of a conductivity controller

A conductivity controller plays a crucial role in ensuring the proper functioning of various industrial processes that rely on the measurement and control of conductivity levels. This job requires a high level of attention to detail, as well as a strong understanding of the principles of conductivity and how it relates to the specific industry in which the controller is working.

One of the primary responsibilities of a conductivity controller is to monitor and adjust conductivity levels in a given system to ensure that they fall within the desired range. This may involve regularly testing samples of the solution being monitored, as well as making adjustments to the system’s settings based on the results of these tests. The controller must be able to accurately interpret the data provided by the conductivity meter and make informed decisions about how to maintain the desired conductivity levels.

In addition to monitoring and adjusting conductivity levels, a conductivity controller may also be responsible for calibrating and maintaining the conductivity meter itself. This involves regularly checking the accuracy of the meter, as well as making any necessary adjustments or repairs to ensure that it continues to provide reliable data. The controller must also keep detailed records of all calibration and maintenance activities to ensure that the meter is functioning properly at all times.

Another important aspect of the conductivity controller‘s job is to troubleshoot any issues that may arise with the conductivity meter or the system being monitored. This may involve identifying and resolving problems with the meter’s sensors, as well as investigating any fluctuations in conductivity levels that could indicate a larger issue with the system. The controller must be able to quickly and accurately diagnose these issues in order to prevent any disruptions to the industrial process.

In some cases, a conductivity controller may also be responsible for training other employees on how to use the conductivity meter and interpret its data. This requires a strong understanding of the principles of conductivity and the ability to effectively communicate this information to others. The controller must be able to explain complex concepts in a clear and concise manner, as well as provide hands-on training to ensure that all employees are able to use the meter effectively.

Overall, the role of a conductivity controller is a critical one in many industrial settings. By monitoring and adjusting conductivity levels, calibrating and maintaining the conductivity meter, troubleshooting issues, and training other employees, the controller plays a key role in ensuring the smooth operation of various industrial processes. This job requires a high level of technical expertise, as well as strong communication and problem-solving skills. Conductivity controllers must be able to work independently and make quick, informed decisions to keep industrial processes running smoothly and efficiently.

Qualifications and Skills Required for a conductivity controller

A conductivity controller is a vital component in various industries, including water treatment, food and beverage production, and pharmaceutical manufacturing. This device is responsible for monitoring and regulating the conductivity of a liquid, ensuring that it falls within a specified range. To excel in this role, individuals must possess a unique set of qualifications and skills that enable them to effectively perform their duties.

One of the primary qualifications required for a conductivity controller is a strong educational background in a relevant field. Most employers prefer candidates with a degree in chemistry, chemical engineering, or a related discipline. This educational foundation provides individuals with the necessary knowledge of chemical principles and processes, which are essential for understanding the intricacies of conductivity control.

In addition to a solid educational background, candidates for a conductivity controller position must also possess practical experience in the field. This experience can be gained through internships, co-op programs, or previous employment in a related role. Hands-on experience allows individuals to develop the skills and expertise needed to effectively operate and maintain conductivity control systems.

Furthermore, individuals applying for a conductivity controller position must have a strong understanding of instrumentation and control systems. This includes knowledge of sensors, transmitters, controllers, and other devices used in conductivity measurement and regulation. Proficiency in reading and interpreting technical drawings, schematics, and manuals is also essential for effectively troubleshooting and maintaining conductivity control systems.

Moreover, candidates for a conductivity controller position must have excellent analytical and problem-solving skills. They must be able to quickly identify issues with conductivity levels, determine the root cause of the problem, and implement appropriate solutions. Strong critical thinking skills are essential for making informed decisions and optimizing conductivity control processes.

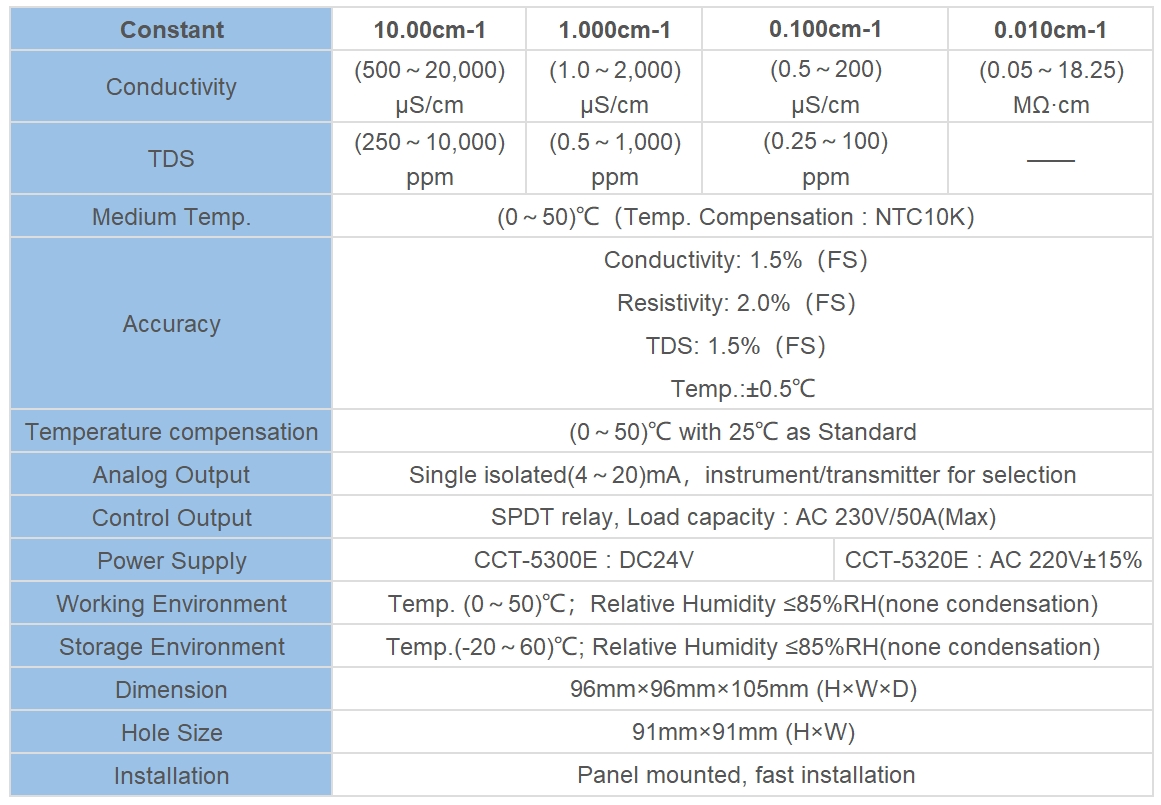

| Model | EC-1800 online conductivity controller |

| Range | 0-2000/4000uS/cm 0-20/200mS/cm |

| 0-1000/2000PPM | |

| Accuracy | 1.5%, 2%, 3%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25\u2103 |

| Oper. Temp. | Normal 0\uff5e50\u2103; High temp 0\uff5e120\u2103 |

| Sensor | C=0.1/1.0/10.0cm-1 |

| Display | 128*64 LCD Screen |

| Communication | 4-20mA output/2-10V/1-5V/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V\u00b110% 50/60Hz or AC 110V\u00b110% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0\uff5e50\u2103 |

| Relative humidity\u226485% | |

| Dimensions | 96\u00d796\u00d7100mm(H\u00d7W\u00d7L) |

| Hole Size | 92\u00d792mm(H\u00d7W) |

| Installation Mode | Embedded |

Effective communication skills are also crucial for individuals in this role. Conductivity controllers often work closely with other team members, including engineers, technicians, and operators. Clear and concise communication is essential for coordinating tasks, sharing information, and resolving issues in a timely manner.

Furthermore, attention to detail is a key attribute for a successful conductivity controller. Monitoring and regulating conductivity levels requires precision and accuracy to ensure that the liquid meets the required specifications. Individuals in this role must be meticulous in their work, carefully monitoring readings and making adjustments as needed to maintain optimal conductivity levels.

In conclusion, a conductivity controller plays a critical role in ensuring the quality and consistency of liquid products in various industries. To excel in this position, individuals must possess a unique set of qualifications and skills, including a strong educational background, practical experience, knowledge of instrumentation and control systems, analytical and problem-solving skills, effective communication abilities, attention to detail, and a commitment to safety and compliance. By meeting these requirements, individuals can effectively perform their duties as conductivity controllers and contribute to the success of their organization.