Benefits of Using Elcometer conductivity meter in Industrial Applications

In industrial applications, the measurement of conductivity is crucial for ensuring the quality and efficiency of processes. One of the most reliable and accurate tools for measuring conductivity is the Elcometer conductivity meter. This advanced instrument offers a wide range of benefits that make it an essential tool for various industries.

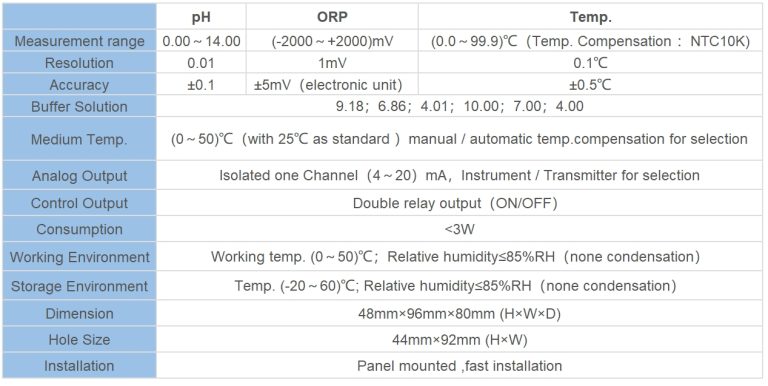

| Model | EC-810 Conductivity/resistivity controller |

| Range | 0-200/2000/4000/10000uS/cm |

| 0-20/200mS/cm 0-18.25MΩ | |

| Accuracy | Conductivity:1.5%; Resistivity:2.0%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25℃ |

| Oper. Temp. | Normal 0~50℃; High temp 0~120℃ |

| Sensor | 0.01/0.02/0.1/1.0/10.0cm-1 |

| Display | LCD Screen |

| Current Output | 4-20mA output/2-10V/1-5V |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×100mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

One of the key benefits of using an Elcometer conductivity meter is its high level of accuracy. This instrument is designed to provide precise and reliable measurements, allowing users to monitor conductivity levels with confidence. This accuracy is essential for ensuring that processes are running smoothly and that products meet quality standards.

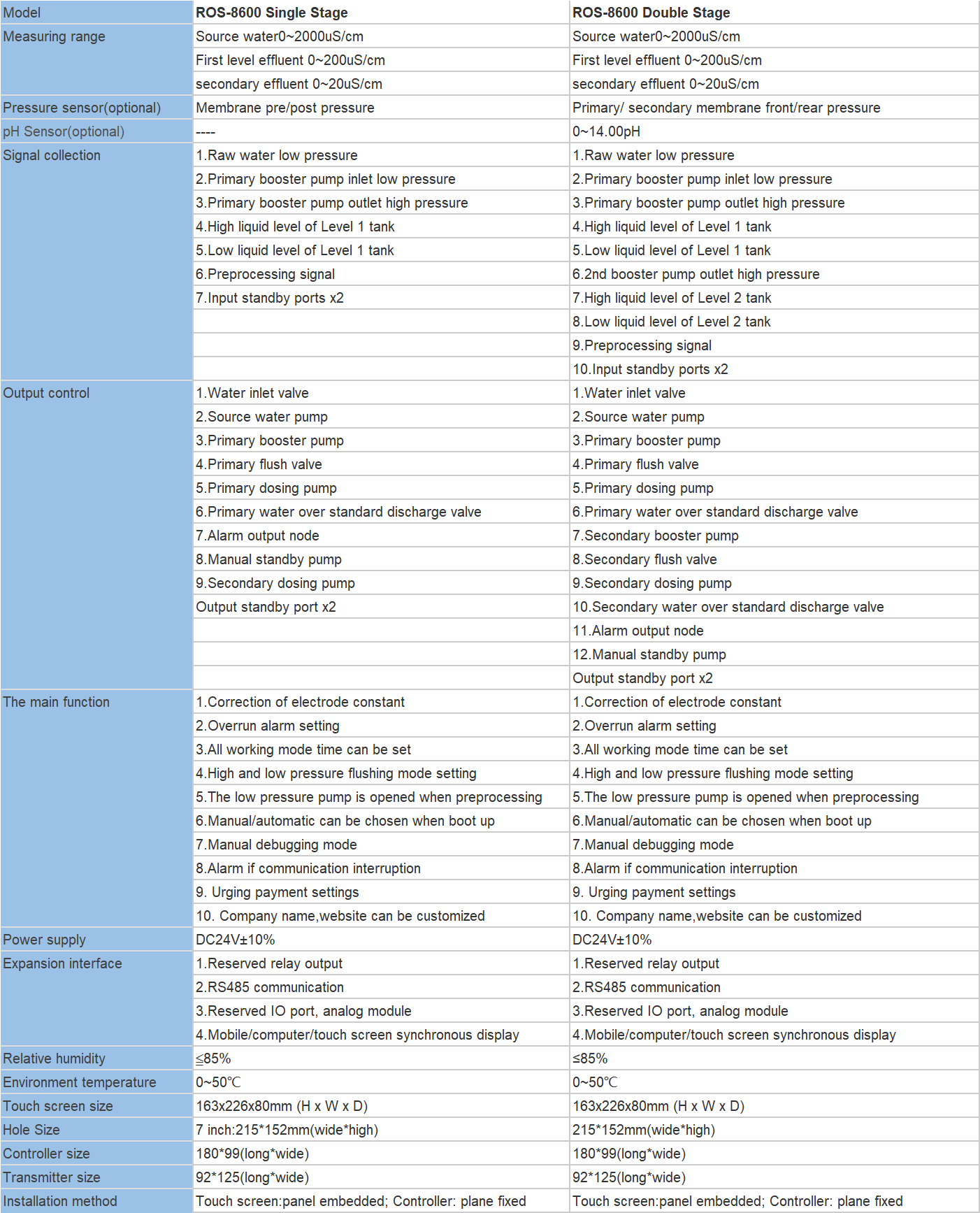

| ROS-8600 RO Program Control HMI Platform | ||

| Model | ROS-8600 Single Stage | ROS-8600 Double Stage |

| Measuring range | Source water0~2000uS/cm | Source water0~2000uS/cm |

| First level effluent 0~200uS/cm | First level effluent 0~200uS/cm | |

| secondary effluent 0~20uS/cm | secondary effluent 0~20uS/cm | |

| Pressure sensor(optional) | Membrane pre/post pressure | Primary/ secondary membrane front/rear pressure |

| ph sensor(optional) | —- | 0~14.00pH |

| Signal collection | 1.Raw water low pressure | 1.Raw water low pressure |

| 2.Primary booster pump inlet low pressure | 2.Primary booster pump inlet low pressure | |

| 3.Primary booster pump outlet high pressure | 3.Primary booster pump outlet high pressure | |

| 4.High liquid level of Level 1 tank | 4.High liquid level of Level 1 tank | |

| 5.Low liquid level of Level 1 tank | 5.Low liquid level of Level 1 tank | |

| 6.Preprocessing signal | 6.2nd booster pump outlet high pressure | |

| 7.Input standby ports x2 | 7.High liquid level of Level 2 tank | |

| 8.Low liquid level of Level 2 tank | ||

| 9.Preprocessing signal | ||

| 10.Input standby ports x2 | ||

| Output control | 1.Water inlet valve | 1.Water inlet valve |

| 2.Source water pump | 2.Source water pump | |

| 3.Primary booster pump | 3.Primary booster pump | |

| 4.Primary flush valve | 4.Primary flush valve | |

| 5.Primary dosing pump | 5.Primary dosing pump | |

| 6.Primary water over standard discharge valve | 6.Primary water over standard discharge valve | |

| 7.Alarm output node | 7.Secondary booster pump | |

| 8.Manual standby pump | 8.Secondary flush valve | |

| 9.Secondary dosing pump | 9.Secondary dosing pump | |

| Output standby port x2 | 10.Secondary water over standard discharge valve | |

| 11.Alarm output node | ||

| 12.Manual standby pump | ||

| Output standby port x2 | ||

| The main function | 1.Correction of electrode constant | 1.Correction of electrode constant |

| 2.Overrun alarm setting | 2.Overrun alarm setting | |

| 3.All working mode time can be set | 3.All working mode time can be set | |

| 4.High and low pressure flushing mode setting | 4.High and low pressure flushing mode setting | |

| 5.The low pressure pump is opened when preprocessing | 5.The low pressure pump is opened when preprocessing | |

| 6.Manual/automatic can be chosen when boot up | 6.Manual/automatic can be chosen when boot up | |

| 7.Manual debugging mode | 7.Manual debugging mode | |

| 8.Alarm if communication interruption | 8.Alarm if communication interruption | |

| 9. Urging payment settings | 9. Urging payment settings | |

| 10. Company name,website can be customized | 10. Company name,website can be customized | |

| Power supply | DC24V±10% | DC24V±10% |

| Expansion interface | 1.Reserved relay output | 1.Reserved relay output |

| 2.RS485 communication | 2.RS485 communication | |

| 3.Reserved IO port, analog module | 3.Reserved IO port, analog module | |

| 4.Mobile/computer/touch screen synchronous display | 4.Mobile/computer/touch screen synchronous display | |

| Relative humidity | ≦85% | ≤85% |

| Environment temperature | 0~50℃ | 0~50℃ |

| Touch screen size | 163x226x80mm (H x W x D) | 163x226x80mm (H x W x D) |

| Hole Size | 7 inch:215*152mm(wide*high) | 215*152mm(wide*high) |

| Controller size | 180*99(long*wide) | 180*99(long*wide) |

| Transmitter size | 92*125(long*wide) | 92*125(long*wide) |

| Installation method | Touch screen:panel embedded; Controller: plane fixed | Touch screen:panel embedded; Controller: plane fixed |

In addition to accuracy, the Elcometer conductivity meter also offers a high level of durability and reliability. This instrument is built to withstand the harsh conditions of industrial environments, making it a reliable tool for daily use. Its robust construction ensures that it can withstand the rigors of industrial settings, providing users with a long-lasting and dependable tool for measuring conductivity.

Another benefit of using an Elcometer conductivity meter is its ease of use. This instrument is designed with user-friendly features that make it simple and straightforward to operate. With intuitive controls and clear displays, users can easily navigate the instrument and obtain accurate measurements quickly and efficiently. This ease of use makes the Elcometer conductivity meter an ideal tool for both experienced professionals and those new to conductivity measurement.

Furthermore, the Elcometer conductivity meter offers a wide range of measurement capabilities, allowing users to measure conductivity levels across a broad spectrum. This versatility makes it a versatile tool for a variety of industrial applications, from water treatment to chemical processing. With the ability to measure conductivity in different solutions and environments, users can rely on the Elcometer conductivity meter for a wide range of applications.

Additionally, the Elcometer conductivity meter is designed with advanced features that enhance its functionality and performance. From automatic temperature compensation to data logging capabilities, this instrument offers a range of features that make it a valuable tool for industrial applications. These advanced features help users to obtain accurate and reliable measurements, ensuring that processes run smoothly and efficiently.

Overall, the Elcometer conductivity meter offers a range of benefits that make it an essential tool for industrial applications. From its high level of accuracy and durability to its ease of use and advanced features, this instrument provides users with a reliable and versatile tool for measuring conductivity. Whether used in water treatment, chemical processing, or other industrial applications, the Elcometer conductivity meter is a valuable instrument that helps ensure the quality and efficiency of processes.