Table of Contents

Benefits of Upgrading to Fleck 5600 Backwash Valve

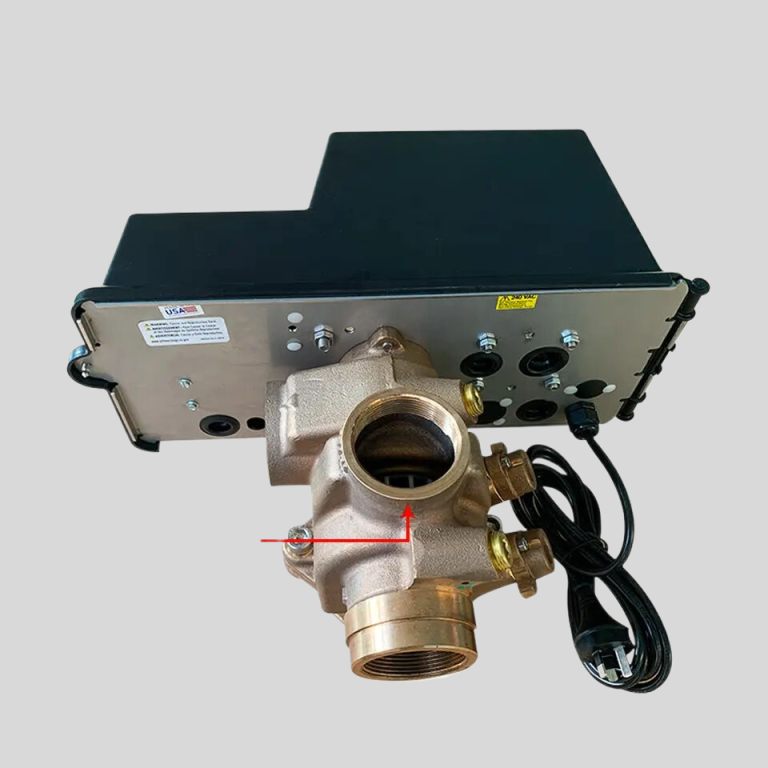

If you are in the market for a new backwash valve for your water treatment system, you may want to consider upgrading to the Fleck 5600 backwash valve. This valve is known for its reliability, efficiency, and ease of use, making it a popular choice among homeowners and businesses alike.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Pressure |

| 5600 | 0.8125″/1.050″ O.D. | 1/2″NPTF | 1600-3/8″ | 2-1/2″-8NPSM | 3W | 2.1MPa |

| 5600 | 0.8125″/1.050″ O.D. | 1/2″NPTF | 1600-3/8″ | 2-1/2″-8NPSM | 3W | 0.14-0.84MPa |

In addition to its durability, the Fleck 5600 backwash valve is also highly efficient. This valve is designed to maximize the efficiency of your water treatment system, ensuring that it operates at peak performance at all times. This can help to improve the quality of your water, as well as reduce the amount of water and energy that is wasted during the backwashing process.

Another benefit of upgrading to the Fleck 5600 backwash valve is its ease of use. This valve is designed to be user-friendly, with simple controls and easy-to-follow instructions. This means that you can easily adjust the settings on your valve to meet your specific needs, without having to worry about complicated programming or confusing manuals.

Furthermore, the Fleck 5600 backwash valve is also highly versatile. This valve is compatible with a wide range of water treatment systems, making it a versatile option for homeowners and businesses with different needs and requirements. Whether you have a small residential system or a large commercial operation, the Fleck 5600 backwash valve can be easily integrated into your existing setup.

Overall, upgrading to the Fleck 5600 backwash valve can offer a number of benefits for your water treatment system. From its durability and efficiency to its ease of use and versatility, this valve is a reliable and effective option for anyone looking to improve the performance of their water treatment system.

In conclusion, if you are in the market for a new backwash valve, consider upgrading to the Fleck 5600. With its durability, efficiency, ease of use, and versatility, this valve offers a number of benefits that can help to improve the performance of your water treatment system. Upgrade to the Fleck 5600 backwash valve today and experience the difference for yourself.

Troubleshooting Common Issues with Fleck 5600 Backwash Valve

The Fleck 5600 backwash valve is a popular choice for water treatment systems due to its reliability and efficiency. However, like any mechanical device, it can experience issues that may require troubleshooting. In this article, we will discuss some common problems that users may encounter with the Fleck 5600 backwash valve and provide solutions to help resolve them.

One common issue that users may face with the Fleck 5600 backwash valve is a leaking valve. This can be caused by a variety of factors, such as a damaged O-ring or a loose connection. To address this issue, users should first check the O-ring for any signs of wear or damage and replace it if necessary. Additionally, users should ensure that all connections are tight and secure to prevent any leaks from occurring.

Another common problem that users may encounter with the Fleck 5600 backwash valve is a stuck valve. This can occur if debris or sediment becomes lodged in the valve, preventing it from operating properly. To resolve this issue, users should first try to manually open and close the valve to dislodge any debris. If this does not work, users may need to disassemble the valve and clean it thoroughly to remove any obstructions.

Users may also experience issues with the Fleck 5600 backwash valve not cycling properly. This can be caused by a malfunctioning timer or a faulty motor. To troubleshoot this issue, users should first check the timer settings to ensure they are correct. If the timer is functioning properly, users should then inspect the motor for any signs of damage or wear and replace it if necessary.

In some cases, users may find that the Fleck 5600 backwash valve is not backwashing properly. This can be due to a clogged filter or a malfunctioning control valve. To address this issue, users should first check the filter for any debris or sediment and clean or replace it as needed. If the filter is not the issue, users should then inspect the control valve for any signs of damage and repair or replace it if necessary.

Users may also encounter issues with the Fleck 5600 backwash valve not drawing brine properly. This can be caused by a clogged brine line or a malfunctioning brine valve. To troubleshoot this issue, users should first check the brine line for any obstructions and clear them if necessary. If the brine line is clear, users should then inspect the brine valve for any signs of damage and repair or replace it as needed.

In conclusion, the Fleck 5600 backwash valve is a reliable and efficient component of water treatment systems. However, users may encounter issues such as leaking valves, stuck valves, improper cycling, backwashing issues, and brine drawing problems. By following the troubleshooting tips provided in this article, users can address these common problems and ensure that their Fleck 5600 backwash valve operates smoothly and effectively.