Table of Contents

Benefits of Using High Temperature Water Flow Meters in Industrial Applications

High temperature water flow meters are essential tools in various industrial applications where accurate measurement of water flow at elevated temperatures is required. These specialized flow meters are designed to withstand the harsh conditions of high-temperature environments, making them ideal for use in industries such as chemical processing, power generation, and food and beverage production.

One of the key benefits of using high temperature water flow meters is their ability to provide accurate and reliable measurements even in extreme conditions. These flow meters are specifically engineered to handle temperatures ranging from 100°C to 200°C, ensuring that they can effectively monitor water flow in processes where traditional flow meters would fail.

In addition to their durability, high temperature water flow meters offer a high level of precision, allowing for precise control of water flow rates in industrial processes. This level of accuracy is crucial in industries where even small variations in flow rates can have a significant impact on product quality and process efficiency.

Furthermore, high temperature water flow meters are designed to be easy to install and maintain, reducing downtime and ensuring continuous operation. With features such as remote monitoring capabilities and self-diagnostic functions, these flow meters provide real-time data that can help operators optimize their processes and identify potential issues before they escalate.

| Model | pH/ORP-5500 pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP: (-2000~+2000)mV; Temp.:(0.0~99.9)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | Range: (0~120)°C; element: Pt1000 |

| Buffer Solution | pH value 9.18; 6.86; 4.01; 10.00; 7.00; 4.00 |

| Medium Temp. | (0~50)°C (with 25°C as standard) manual/automatic temp. compensation for selection |

| Analog output | Isolated (4~20)mA, Instrument/Transmitter for selection |

| Control Output | Double relay output (ON/OFF); AC 240V/3A |

| Working Environment | Temp.(0~50)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V; AC 110V; AC220V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx105mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

Moreover, high temperature water flow meters are cost-effective solutions for industrial processes that require accurate measurement of water flow at elevated temperatures. By providing reliable data and reducing the risk of downtime, these flow meters help companies save money in the long run by improving process efficiency and minimizing waste.

In conclusion, high temperature water flow meters offer a range of benefits for industrial applications where accurate measurement of water flow at elevated temperatures is essential. From their durability and precision to their ease of installation and maintenance, these specialized flow meters provide a reliable and cost-effective solution for monitoring water flow in a variety of industries. By investing in high temperature water flow meters, companies can improve process efficiency, reduce downtime, and ultimately enhance their overall productivity.

How to Choose the Right High Temperature Water flow meter for Your Specific Needs

When it comes to selecting a high temperature water flow meter, there are several factors to consider in order to ensure that you choose the right one for your specific needs. High temperature water flow meters are designed to accurately measure the flow rate of hot water in various industrial applications, such as in boilers, heat exchangers, and other high-temperature processes. These meters are essential for monitoring and controlling the flow of hot water to ensure optimal performance and efficiency.

One of the most important factors to consider when choosing a high temperature water flow meter is the temperature range that it can withstand. High temperature water flow meters are specifically designed to handle hot water temperatures, typically ranging from 100°C to 200°C or even higher. It is crucial to select a flow meter that can withstand the specific temperature range of your application to ensure accurate and reliable measurements.

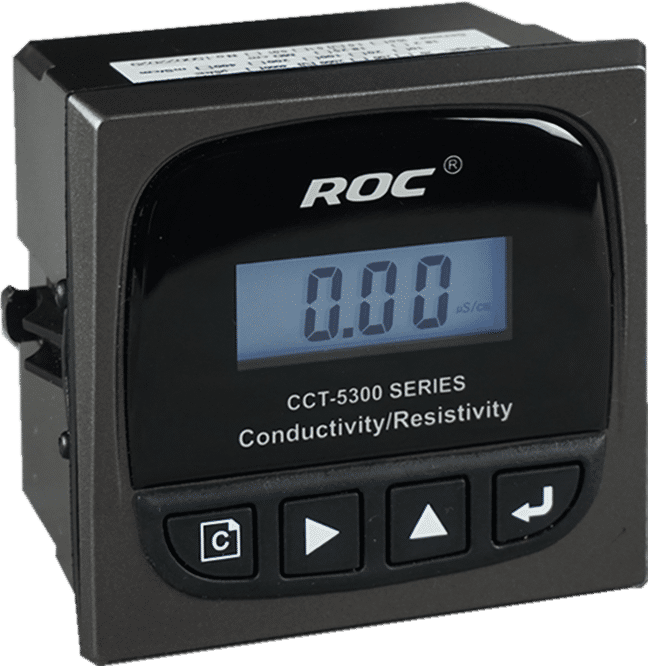

| Model | RM-220s/ER-510 resistivity controller |

| Range | 0-20uS/cm; 0-18.25MΩ |

| Accuracy | 2.0%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25℃ |

| Oper. Temp. | Normal 0~50℃; High temp 0~120℃ |

| Sensor | 0.01/0.02 cm-1 |

| Display | LCD Screen |

| Communication | ER-510:4-20mA output/RS485 |

| Output | ER-510:High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 48×96×100mm(H×W×L) |

| Hole Size | 45×92mm(H×W) |

| Installation Mode | Embedded |

In addition to temperature range, it is also important to consider the flow rate range of the high temperature water flow meter. Flow meters are available in various sizes and designs to accommodate different flow rates, so it is essential to choose a flow meter that can accurately measure the flow rate of your hot water system. Selecting a flow meter with the appropriate flow rate range will ensure that you get accurate and reliable measurements for your specific application.

Another important factor to consider when choosing a high temperature water flow meter is the type of technology used in the meter. There are several types of flow meter technologies available, such as electromagnetic, ultrasonic, and thermal mass flow meters, each with its own advantages and limitations. It is important to select a flow meter technology that is suitable for your specific application and provides the level of accuracy and reliability that you require.

Furthermore, it is essential to consider the installation requirements of the high temperature water flow meter. Some flow meters require specific installation conditions, such as straight pipe lengths or mounting orientations, in order to provide accurate measurements. It is important to ensure that the flow meter can be installed properly in your hot water system to avoid any potential issues with measurement accuracy.

Additionally, it is important to consider the maintenance requirements of the high temperature water flow meter. Regular maintenance is essential to ensure that the flow meter continues to provide accurate and reliable measurements over time. Some flow meters may require periodic calibration or cleaning to maintain their performance, so it is important to consider the maintenance requirements of the flow meter when making your selection.

In conclusion, choosing the right high temperature water flow meter for your specific needs requires careful consideration of factors such as temperature range, flow rate range, technology, installation requirements, and maintenance requirements. By taking these factors into account, you can select a flow meter that will provide accurate and reliable measurements for your hot water system, ensuring optimal performance and efficiency.