Understanding the Functionality of a ph controller

A ph controller is a device used to monitor and regulate the pH level of a solution. pH, which stands for “potential of hydrogen,” is a measure of the acidity or alkalinity of a solution. The pH scale ranges from 0 to 14, with 0 being highly acidic, 7 being neutral, and 14 being highly alkaline. Maintaining the correct pH level is crucial in various industries, such as water treatment, agriculture, and food production, as it can affect the quality and effectiveness of processes and products.

The primary function of a ph controller is to continuously monitor the pH level of a solution and make adjustments to maintain it within a specific range. This is achieved through a combination of sensors, controllers, and actuators. The ph sensor is the key component of the system, as it is responsible for measuring the pH level of the solution. The sensor typically consists of a glass electrode that generates a voltage signal proportional to the pH level.

The ph controller receives the signal from the ph sensor and compares it to a setpoint value, which is the desired pH level of the solution. If the measured pH deviates from the setpoint, the controller sends a signal to the actuator, which is usually a dosing pump or valve that adds acid or base to the solution to adjust the pH level. The controller continues to monitor the pH level and make adjustments as needed to keep it within the desired range.

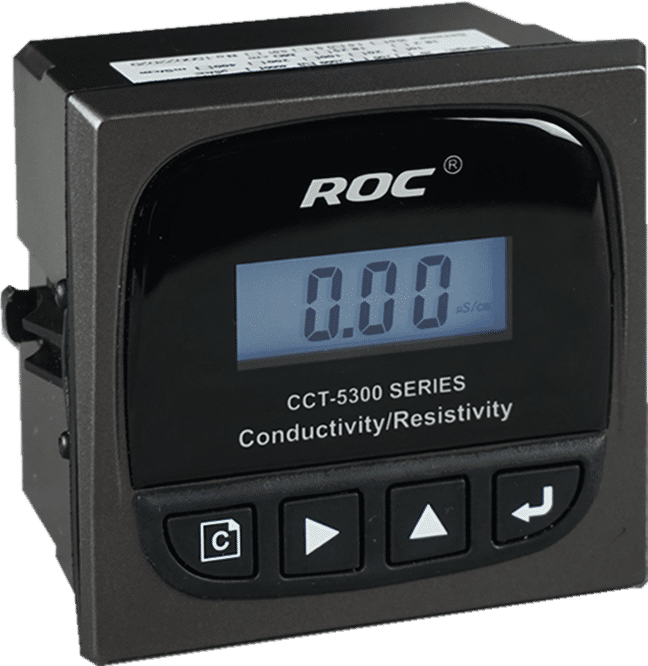

| Model | pH/ORP-3500 pH/orp meter |

| Range | pH:0.00~14.00 ; ORP: (-2000~+2000)mV; Temp.:(0.0~99.9)\u00b0C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1\u00b0C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5\u00b0C |

| Temp. compensation | Range: (0~120)\u00b0C; element: Pt1000 |

| Buffer Solution | 9.18; 6.86; 4.01; 10.00; 7.00; 4.00 |

| Medium Temp. | (0~50)\u00b0C (with 25\u00b0C as standard) manual/automatic temp. compensation for selection |

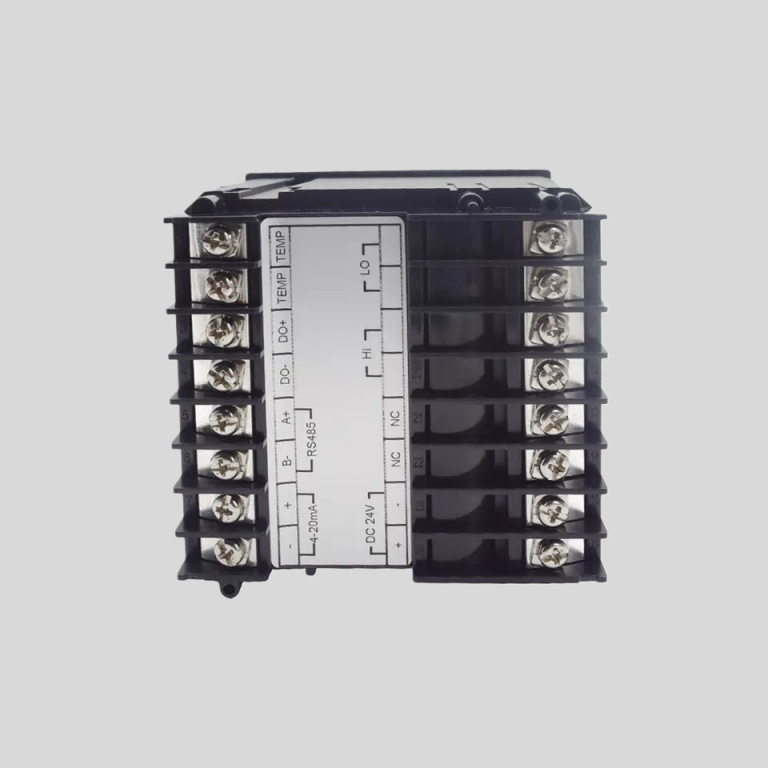

| Analog output | Isolated one Channel(4~20)mA, Instrument/Transmitter for selection |

| Control Output | Double relay output (single contact ON/OFF) |

| Working Environment | Temp.(0~50)\u2103; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)\u2103;Relative Humidity \u226485%RH (none condensation) |

| Power Supply | DC 24V; AC 110V; AC220V |

| Power consumption | <3W |

| Dimension | 48mmx96mmx80mm(HxWxD) |

| Hole Size | 44mmx92mm(HxW) |

| Installation | Panel mounted, fast installation |

One of the key features of a ph controller is its ability to provide real-time monitoring and control of the pH level. This allows for immediate corrective action to be taken in response to changes in the pH level, ensuring that the solution remains within the specified range. Additionally, some pH controllers have advanced features such as data logging and remote monitoring, which allow for historical data to be recorded and analyzed, and for the system to be monitored and controlled remotely.

In addition to maintaining the pH level of a solution, pH controllers can also be used to automate processes that require precise pH control. For example, in water treatment plants, pH controllers are used to adjust the pH of the water to optimize the effectiveness of disinfection processes. In agriculture, pH controllers can be used to regulate the pH of irrigation water to ensure optimal nutrient uptake by plants. In food production, pH controllers are used to control the acidity of food products to ensure safety and quality.

Overall, pH controllers play a crucial role in a wide range of industries by providing accurate and reliable monitoring and control of pH levels. By maintaining the correct pH level of a solution, pH controllers help to ensure the quality and effectiveness of processes and products. With their advanced features and capabilities, pH controllers are essential tools for achieving precise pH control and automation in various applications.