Understanding the Importance of Liquid pH Sensors in Industrial Applications

Liquid pH sensors play a crucial role in various industrial applications, providing accurate measurements of the acidity or alkalinity of a liquid. These sensors are essential for maintaining the quality and efficiency of processes in industries such as pharmaceuticals, food and beverage, water treatment, and chemical manufacturing. Understanding the importance of liquid pH sensors in industrial settings is key to ensuring optimal performance and productivity.

One of the primary reasons why liquid pH sensors are vital in industrial applications is their ability to monitor and control the pH levels of liquids. pH is a critical parameter that can affect the quality of products and the efficiency of processes. For example, in the food and beverage industry, maintaining the correct pH level is essential for ensuring the safety and taste of products. In water treatment plants, pH sensors are used to monitor the acidity or alkalinity of water to ensure it meets regulatory standards.

Liquid pH sensors are also crucial for detecting and preventing potential issues in industrial processes. Changes in pH levels can indicate the presence of contaminants or impurities in liquids, which can lead to product defects or equipment damage. By continuously monitoring pH levels, industries can identify problems early on and take corrective actions to prevent costly downtime and production losses.

| ROS-2015 Single Stage Reverse Osmosis Program Controller | |

| 1.water source water tank without water protection | |

| 2. low pressure protection | |

| Acquisition signal | 3.pure water tank full protection |

| 4.high pressure protection | |

| 5.external control(manual/automatic switch) | |

| 1.water inlet valve | |

| Output control | 2. flush valve |

| 3. low pressure pump | |

| 4.high pressure pump | |

| AC220v±10% 50/60Hz | |

| Power supply | AC110v±10% 50/60Hz |

| DC24v±10% | |

| Control output | 5A/250V AC |

| Flush the way | Low pressure flush/ high pressure flush |

| Relative humidity | ≤85% |

| Ambient temperature | 0~50℃ |

| Hole Size | 45*92mm(high*wide) |

| Installation method | The embedded |

| Display usage | Standard RO process flow chart, supporting LED dynamic display |

| Process control | When the system is turned on for the first time,the system performs 30s membrane flushing, |

| instructions | and flush 10s when the machine is running and the water tank is full. Run continuously for 3h |

| or stand by for 3h when the water is full, automatically intervene in flushing for 10s | |

In addition to monitoring pH levels, liquid pH sensors play a key role in optimizing processes and improving efficiency. By providing real-time data on pH levels, these sensors enable industries to make informed decisions and adjustments to their processes. For example, in chemical manufacturing, pH sensors are used to control the addition of chemicals and adjust reaction conditions to achieve the desired product quality.

Furthermore, liquid pH sensors help industries comply with regulatory requirements and quality standards. Many industries are subject to strict regulations regarding the pH levels of their products or effluents. By using accurate and reliable pH sensors, industries can ensure that they meet these requirements and avoid potential fines or penalties.

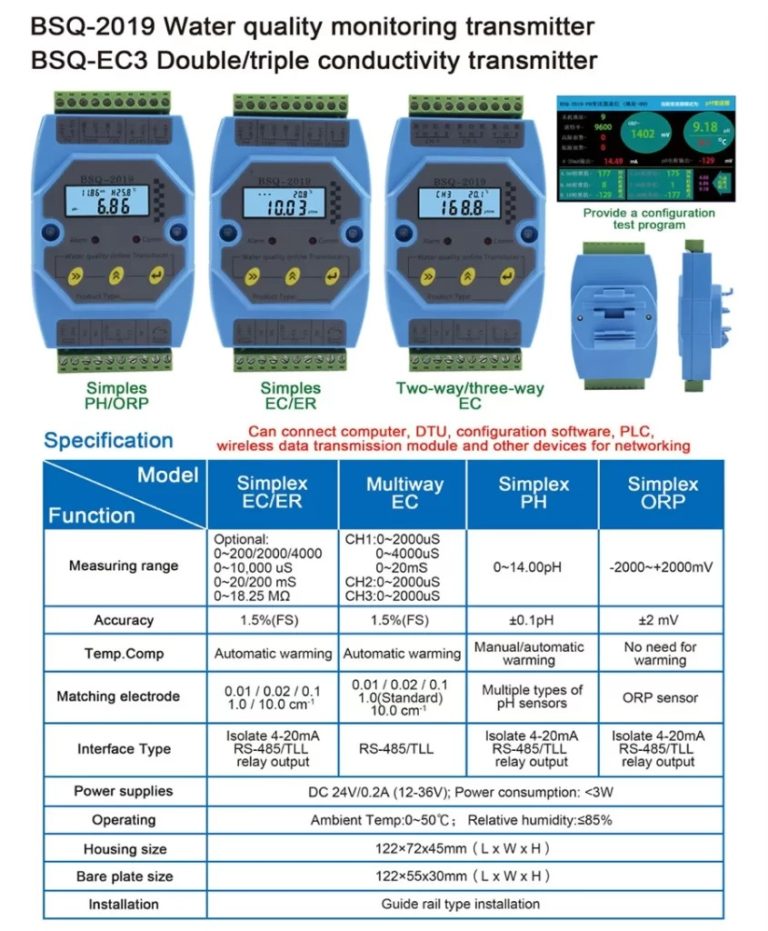

The advancements in sensor technology have led to the development of more sophisticated and reliable liquid pH sensors. Modern pH sensors are designed to be durable, accurate, and easy to use, making them ideal for industrial applications. Some sensors are equipped with features such as automatic temperature compensation, self-calibration, and digital communication capabilities, which enhance their performance and reliability.

Overall, liquid pH sensors are indispensable tools for industries that rely on accurate pH measurements to maintain product quality, optimize processes, and comply with regulations. By investing in high-quality pH sensors and integrating them into their operations, industries can enhance their efficiency, productivity, and competitiveness in the market.

| Model | pH/ORP-810 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~50℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×100mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In conclusion, understanding the importance of liquid pH sensors in industrial applications is essential for ensuring the success and sustainability of businesses. These sensors play a critical role in monitoring pH levels, detecting issues, optimizing processes, and complying with regulations. By leveraging the capabilities of modern pH sensors, industries can achieve greater control over their processes and achieve higher levels of performance and quality.