Benefits of Using Mechanical Valves in Industrial Applications

Mechanical valves play a crucial role in various industrial applications, providing a reliable and efficient way to control the flow of fluids or gases within a system. These valves are designed to withstand high pressures and temperatures, making them ideal for use in demanding environments where precision and durability are essential.

In addition to their precision, mechanical valves are also known for their durability and reliability. These valves are typically made from high-quality materials such as stainless steel or brass, which are able to withstand the harsh conditions often found in industrial settings. This means that mechanical valves are less likely to fail or require frequent maintenance, resulting in lower operating costs and increased productivity for businesses.

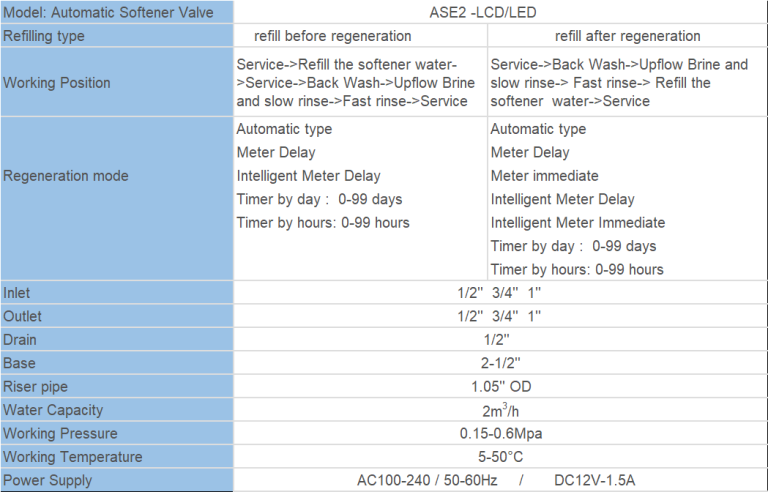

| Model | MSS2 | ASS2 -LCD/LED |

| Working Position | Service->Back Wash->Upflow Brine and slow rinse-> Fast rinse->Refill the softener water->Service . | |

| Regeneration mode | Manual | Automatic type |

| Meter Delay | ||

| Meter immediate | ||

| Intelligent Meter Delay | ||

| Intelligent Meter Immediate | ||

| Timer by day : 0-99 days | ||

| Timer by hours: 0-99 hours | ||

| Inlet | 3/4” | 3/4” 1” |

| Outlet | 3/4” | 3/4” 1” |

| Drain | 1/2” | 1/2” |

| Base | 2-1/2” | 2-1/2” |

| Riser pipe | 1.05” OD | 1.05” OD |

| Water Capacity | 2m3/h | 2m3/h |

| Working Pressure | 0.15-0.6Mpa | 0.15-0.6Mpa |

| Working Temperature | 5-50° C | |

| Power Supply | No Need Power | AC100-240 / 50-60Hz / DC12V-1.5A |

Another advantage of using mechanical valves in industrial applications is their versatility. These valves come in a variety of designs and configurations, allowing them to be used in a wide range of applications, from simple on/off control to more complex flow regulation systems. This flexibility makes mechanical valves a popular choice for many different industries, including oil and gas, chemical processing, and manufacturing.

Furthermore, mechanical valves are often more cost-effective than other types of valves, such as pneumatic or electric valves. Because mechanical valves do not require external power sources to operate, they can be a more economical option for businesses looking to control costs without sacrificing performance. Additionally, the long lifespan of mechanical valves means that businesses can save money on replacement and maintenance costs over time.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 5600 | 0.8125″/1.050″ O.D. | 1/2″NPTF | 1600-3/8″ | 2-1/2″-8NPSM | 3W | 1℃-43℃ |

Overall, the benefits of using mechanical valves in industrial applications are clear. From their precision and durability to their versatility and cost-effectiveness, mechanical valves offer a reliable and efficient solution for controlling the flow of fluids or gases in a wide range of settings. Whether you are looking to improve the performance of your manufacturing process or ensure the safety of your oil and gas operations, mechanical valves are a smart choice for businesses looking to optimize their operations and maximize their productivity.