“Effortlessly connect and disconnect with plastic air line quick connectors.”

Table of Contents

Benefits of Using Plastic Air Line Quick Connectors

Plastic air line quick connectors are essential components in pneumatic systems, providing a convenient and efficient way to connect and disconnect air lines. These connectors offer a range of benefits that make them a popular choice for various applications. In this article, we will explore the advantages of using plastic air line quick connectors and why they are a preferred option for many industries.

One of the key benefits of plastic air line quick connectors is their lightweight and durable construction. Made from high-quality materials such as polypropylene or nylon, these connectors are designed to withstand the rigors of daily use in industrial environments. Despite their lightweight nature, plastic air line quick connectors are incredibly strong and resistant to corrosion, making them a reliable choice for connecting air lines in pneumatic systems.

Another advantage of plastic air line quick connectors is their ease of use. These connectors feature a simple push-to-connect design that allows for quick and easy installation without the need for additional tools or equipment. This makes them ideal for applications where frequent connection and disconnection of air lines are required, saving time and effort for operators.

Furthermore, plastic air line quick connectors offer a secure and leak-free connection. The unique design of these connectors ensures a tight seal between the air lines, preventing air leaks and maintaining consistent pressure within the pneumatic system. This not only improves the overall efficiency of the system but also reduces the risk of downtime and costly repairs due to air leaks.

In addition to their practical benefits, plastic air line quick connectors are also cost-effective solutions for connecting air lines in pneumatic systems. Compared to metal connectors, plastic connectors are more affordable without compromising on quality or performance. This makes them a budget-friendly option for businesses looking to optimize their pneumatic systems without breaking the bank.

Moreover, plastic air line quick connectors are versatile components that can be used in a wide range of applications. Whether in automotive, manufacturing, or construction industries, these connectors are suitable for connecting air lines in various pneumatic systems. Their compatibility with different types of air lines and fittings makes them a versatile solution for diverse applications.

Overall, plastic air line quick connectors offer a range of benefits that make them a preferred choice for connecting air lines in pneumatic systems. From their lightweight and durable construction to their ease of use and cost-effectiveness, these connectors provide a reliable and efficient solution for businesses looking to optimize their pneumatic systems. With their secure and leak-free connection, plastic air line quick connectors help improve the overall performance and reliability of pneumatic systems, making them an essential component in various industries.

How to Properly Install and Maintain Plastic Air Line Quick Connectors

Plastic air line quick connectors are essential components in pneumatic systems, allowing for quick and easy connections between air lines and various pneumatic devices. Proper installation and maintenance of these connectors are crucial to ensure the efficiency and longevity of the pneumatic system. In this article, we will discuss the steps to properly install and maintain plastic air line quick connectors.

When installing plastic air line quick connectors, it is important to first ensure that the connectors are compatible with the air lines and pneumatic devices being used. Different connectors may have different thread sizes or types, so it is essential to check the specifications of the connectors before installation. Once compatibility is confirmed, the next step is to prepare the air lines for connection.

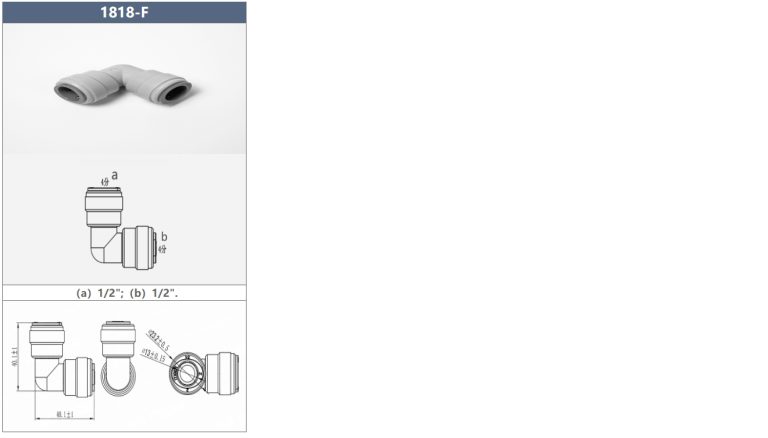

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/14 |

To prepare the air lines, cut the tubing to the desired length using a tubing cutter to ensure a clean and straight cut. Remove any burrs or rough edges from the cut end of the tubing using a deburring tool to prevent air leaks. Insert the tubing into the quick connector until it reaches the tube stop, ensuring that the tubing is fully seated in the connector. It is important to make sure that the tubing is not kinked or bent, as this can restrict airflow and cause leaks.

After the tubing is properly inserted into the quick connector, tighten the compression nut to secure the connection. Use a wrench to tighten the nut until it is snug, but be careful not to over-tighten as this can damage the connector or tubing. Once the connection is secure, test the connection by applying air pressure to the system and checking for any leaks. If there are any leaks, tighten the compression nut further or reseat the tubing in the connector.

Proper maintenance of plastic air line quick connectors is essential to ensure the continued efficiency of the pneumatic system. Regularly inspect the connectors for any signs of wear or damage, such as cracks, breaks, or leaks. If any damage is found, replace the connector immediately to prevent air leaks and system failure. It is also important to clean the connectors regularly to remove any dirt, debris, or contaminants that may affect the performance of the connectors.

To clean plastic air line quick connectors, disconnect the tubing from the connector and use a mild detergent or solvent to clean the connector. Use a soft brush or cloth to scrub the connector and remove any dirt or debris. Rinse the connector thoroughly with clean water and allow it to dry completely before reassembling the connection. It is important to avoid using harsh chemicals or abrasive materials when cleaning the connectors, as this can damage the plastic and compromise the integrity of the connection.

In conclusion, proper installation and maintenance of plastic air line quick connectors are essential to ensure the efficiency and longevity of pneumatic systems. By following the steps outlined in this article, you can ensure that your connectors are properly installed and maintained, allowing for reliable and leak-free connections in your pneumatic system. Remember to always check compatibility, prepare the air lines correctly, tighten connections securely, and regularly inspect and clean the connectors to keep your pneumatic system running smoothly.