“Secure connections, simplified with plastic push in fittings.”

Table of Contents

Benefits of Using Plastic push in fittings in Plumbing Systems

Plastic push-in fittings have become increasingly popular in plumbing systems due to their ease of use, durability, and cost-effectiveness. These fittings are designed to connect pipes without the need for soldering, gluing, or threading, making them a convenient option for both professional plumbers and DIY enthusiasts.

One of the key benefits of using plastic push-in fittings is their simplicity. With traditional fittings, connecting pipes can be a time-consuming and labor-intensive process. However, with push-in fittings, all you need to do is push the pipe into the fitting until it clicks into place. This not only saves time but also reduces the risk of leaks and other issues that can arise from improper installation.

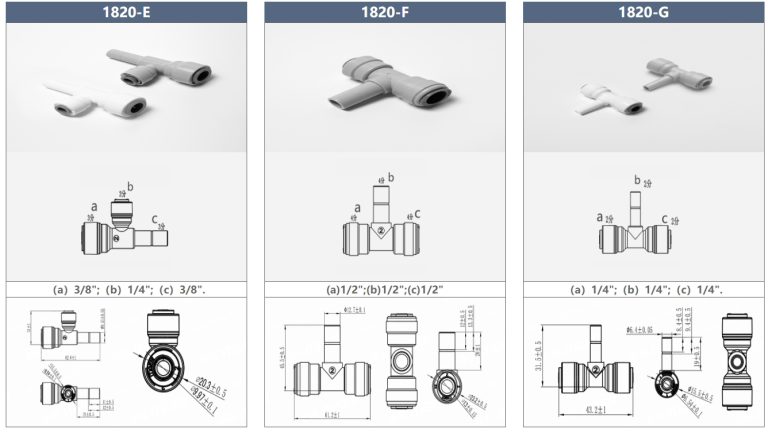

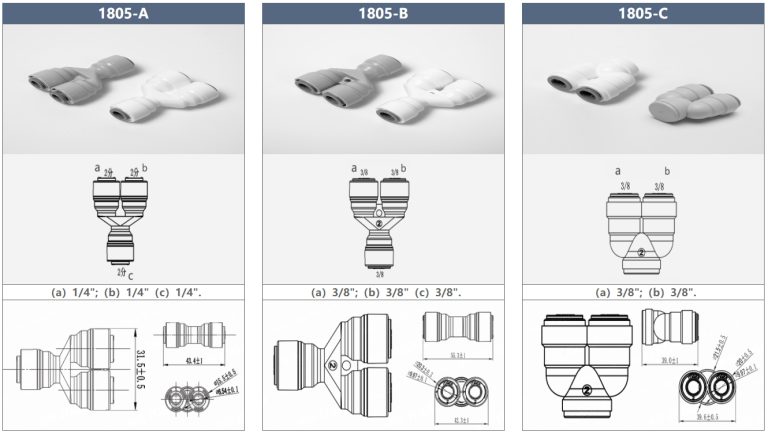

Another advantage of plastic push-in fittings is their versatility. These fittings are available in a wide range of sizes and configurations, making them suitable for a variety of plumbing applications. Whether you are working on a small repair job or a large-scale installation, you can easily find push-in fittings that meet your specific needs.

In addition to their ease of use and versatility, plastic push-in fittings are also highly durable. Made from high-quality materials such as polypropylene or nylon, these fittings are resistant to corrosion, rust, and other forms of damage. This means that once installed, push-in fittings can withstand the test of time, providing a reliable and long-lasting connection between pipes.

Furthermore, plastic push-in fittings are cost-effective. Compared to traditional fittings, which often require additional tools and materials for installation, push-in fittings are a more affordable option. Additionally, because they are so easy to install, you can save money on labor costs by completing the job yourself.

One of the key advantages of plastic push-in fittings is their ability to create a watertight seal. When properly installed, push-in fittings form a secure connection between pipes, preventing leaks and ensuring the smooth flow of water through the plumbing system. This can help to prevent water damage and other costly issues that can arise from leaks.

Moreover, plastic push-in fittings are reusable. Unlike some traditional fittings that can only be used once, push-in fittings can be easily disconnected and reconnected as needed. This makes them a convenient option for situations where pipes may need to be moved or replaced in the future.

In conclusion, plastic push-in fittings offer a wide range of benefits for plumbing systems. From their ease of use and versatility to their durability and cost-effectiveness, push-in fittings are a reliable and efficient option for connecting pipes. Whether you are a professional plumber or a DIY enthusiast, consider using plastic push-in fittings for your next plumbing project.

Common Mistakes to Avoid When Installing Plastic push in fittings

Plastic push-in fittings are a popular choice for many DIY enthusiasts and professionals alike due to their ease of installation and versatility. However, there are some common mistakes that can occur when installing these fittings that can lead to leaks, malfunctions, or even damage to the surrounding plumbing system. In this article, we will discuss some of the most common mistakes to avoid when working with plastic push-in fittings to ensure a successful installation.

One of the most common mistakes that people make when installing plastic push-in fittings is not properly preparing the pipe before inserting it into the fitting. It is essential to ensure that the end of the pipe is cut cleanly and squarely to prevent any leaks or gaps between the pipe and the fitting. Using a pipe cutter or a sharp knife to make a clean cut can help ensure a tight and secure connection.

Another common mistake is not fully inserting the pipe into the fitting. It is crucial to push the pipe all the way into the fitting until it reaches the stop inside the fitting. Failure to do so can result in leaks or a weak connection that may fail over time. Applying a slight twisting motion while pushing the pipe into the fitting can help ensure a secure and tight connection.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/33 |

Using excessive force when installing plastic push-in fittings is another mistake to avoid. While it is essential to push the pipe firmly into the fitting, using too much force can damage the fitting or the pipe, leading to leaks or malfunctions. It is essential to apply steady and even pressure when inserting the pipe into the fitting to avoid any damage.

Not properly supporting the pipe after installation is another common mistake that can lead to issues down the line. It is crucial to secure the pipe in place using clips or brackets to prevent any movement or stress on the fitting. Failure to do so can result in leaks or damage to the fitting over time. Properly supporting the pipe can help ensure a long-lasting and reliable connection.

Failing to test the fitting after installation is another mistake that can lead to problems later on. It is essential to check for any leaks or malfunctions by turning on the water supply and inspecting the fitting for any signs of water leakage. If any issues are detected, it is crucial to address them immediately to prevent any further damage or issues with the plumbing system.

Not using the correct size or type of fitting for the job is another common mistake that can lead to installation issues. It is essential to ensure that the fitting is compatible with the pipe material and size to ensure a proper and secure connection. Using the wrong fitting can result in leaks, malfunctions, or damage to the plumbing system.

In conclusion, plastic push-in fittings are a convenient and versatile option for many plumbing projects. However, it is essential to avoid common mistakes when installing these fittings to ensure a successful and reliable connection. By properly preparing the pipe, fully inserting it into the fitting, using the correct amount of force, supporting the pipe after installation, testing the fitting, and using the correct size and type of fitting, you can avoid issues and ensure a long-lasting and secure connection for your plumbing system.