Table of Contents

Understanding the Functionality of Soft Shift Directional Valves

Soft shift directional valves are integral components in the realm of fluid power systems, particularly in hydraulic and pneumatic applications. These valves are designed to control the direction of fluid flow within a system, thereby influencing the movement of mechanical components. However, what sets soft shift directional valves apart from their counterparts is their unique ability to modulate the speed of this fluid flow, resulting in smoother, quieter, and more efficient operations.

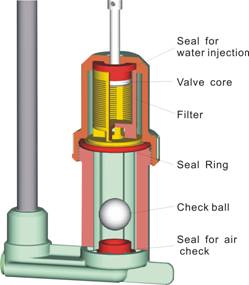

The primary function of a soft shift directional valve is to regulate the flow of fluid, typically oil or air, through a hydraulic or pneumatic system. This is achieved by altering the position of the valve’s internal spool, which in turn changes the direction of the fluid flow. The spool’s position can be adjusted manually, electrically, or pneumatically, depending on the specific design of the valve.

However, the distinguishing feature of a soft shift directional valve lies in its ability to control not just the direction, but also the speed of the fluid flow. This is accomplished through a unique design feature known as a ‘soft shift’ mechanism. This mechanism employs a series of springs and pressure chambers to gradually adjust the position of the spool, rather than abruptly shifting it from one position to another. This gradual shift results in a smoother, more controlled fluid flow, which in turn leads to less noise, less wear and tear on the system components, and overall improved system performance.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 2510 | 1.05″ (1″)O.D. | 1/2″O.D. | 1600-3/8″ | 2-1/2″-8NPSM | 72W | 1℃-43℃ |

| 1650-3/8″ |

The benefits of using a soft shift directional valve are manifold. Firstly, the smooth, gradual shifting of the spool reduces the shock loads that are typically associated with sudden changes in fluid flow direction. This not only minimizes noise and vibration but also extends the lifespan of the system components by reducing wear and tear. Secondly, the ability to control the speed of the fluid flow allows for more precise control over the movement of mechanical components, which can be particularly beneficial in applications that require high levels of precision and accuracy. Lastly, by improving the efficiency of the fluid flow, soft shift directional valves can also contribute to energy savings, making them a cost-effective choice for many applications.

Despite their numerous advantages, it’s important to note that soft shift directional valves may not be suitable for all applications. The soft shift mechanism can add complexity to the valve design, which can increase the cost and maintenance requirements of the valve. Furthermore, the gradual shifting of the spool can result in slower response times, which may not be acceptable in applications that require rapid changes in fluid flow direction.

In conclusion, soft shift directional valves offer a unique solution for controlling the direction and speed of fluid flow in hydraulic and pneumatic systems. Their ability to provide smooth, gradual shifts in fluid flow direction can result in quieter, more efficient operations, and extended component lifespan. However, their suitability for a particular application should be carefully considered, taking into account factors such as cost, maintenance requirements, and response time. With a thorough understanding of their functionality, soft shift directional valves can be effectively utilized to optimize the performance of fluid power systems.

Maintenance Tips for Soft Shift Directional Valves

Soft shift directional valves are integral components in hydraulic systems, playing a crucial role in controlling the flow and direction of fluid within the system. These valves are designed to provide smooth, gradual transitions between states, reducing the shock and vibration typically associated with sudden changes in fluid direction. However, like any mechanical component, soft shift directional valves require regular maintenance to ensure optimal performance and longevity.

| Model | Central tube | Drain | Brine tank connector | Base | Power supply parameters | Maximum power | Pressure parameters | Operating temperature |

| 5600 | 0.8125″/1.050″ O.D. | 1/2″NPTF | 1600-3/8″ | 2-1/2″-8NPSM | 24v,110v,220v-50Hz,60Hz | 3W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 5600SXT | 0.8125″/1.050″ O.D. | 1/2″NPTF | 1600-3/8″ | 2-1/2″-8NPSM | 24v,110v,220v-50Hz,60Hz | 8.4W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 2510 | 1.05″ (1″)O.D. | 1/2″O.D. | 1600-3/8″ | 2-1/2″-8NPSM | 24v,110v,220v-50Hz,60Hz | 72W | 2.1MPa | 1℃-43℃ |

| 1650-3/8″ | 0.14-0.84MPa | |||||||

| 2700 | 1.05″ O.D. | 3/4″NPTF | 3/8″ & 1/2″ | 2-1/2″-8NPSM | 24V,110V,220V-50Hz,60Hz | 74W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 2850 | 1.9″(1.5″)O.D. | 1″NPTM | 3/8″&1/2″ | 4″-8UN | 24v,110v,220v-50Hz,60Hz | 72W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 2900 | 1.9″(1.5″)O.D. | 3/4″NPTM | 3/8″&1/2″ | 4″-8UN | 24v,110v,220v-50Hz,60Hz | 143W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 3150 | 2.375″(2″) O.D. | 2″NPTF | 1″NPTM | 4″-8UN | 24v,110v,220v-50Hz,60Hz | 87W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 3900 | 3.5″(3″) O.D. | 2″NPTF | 1″NPTM | 6″-8UN | 24v,110v,220v-50Hz,60Hz | 171W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 9000 | 1.05″ O.D. | 1/2″NPT | 1600-3/8″ | 2-1/2″-8NPSM | 24v,110v,220v-50Hz,60Hz | 8.9W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 9100 | 1.05″ O.D. | 1/2″NPT | 1600-3/8″ | 2-1/2″-8NPSM | 24v,110v,220v-50Hz,60Hz | 8.9W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa | ||||||||

| 9500 | 1.9″(1.5″) O.D. | 1″NPTF | 3/8″& 1/2″ | 4″-8UN | 24v,110v,220v-50Hz,60Hz | 8.9W | 2.1MPa | 1℃-43℃ |

| 0.14-0.84MPa |

One of the first steps in maintaining a soft shift directional valve is regular inspection. This involves checking the valve for any visible signs of wear and tear, such as cracks, leaks, or corrosion. Any abnormalities should be addressed immediately to prevent further damage. Additionally, the valve’s operation should be monitored to detect any changes in performance. For instance, if the valve is not shifting smoothly or is making unusual noises, it may be an indication of an underlying issue that needs to be addressed.

Cleaning is another essential aspect of soft shift directional valve maintenance. Over time, dirt and debris can accumulate in the valve, potentially causing blockages and impairing its function. Therefore, it is recommended to clean the valve regularly using a suitable cleaning solution. However, care should be taken not to use harsh or abrasive cleaners that could damage the valve’s delicate components.

In addition to these routine maintenance tasks, it is also important to conduct periodic performance tests on the valve. These tests can help identify any potential issues before they become serious problems. For example, a pressure test can be used to check the valve’s ability to handle the system’s operating pressure. If the valve fails this test, it may be an indication that it is worn out and needs to be replaced.

Finally, it is important to keep a record of all maintenance activities performed on the valve. This can help identify patterns or recurring issues, which can be useful in diagnosing problems and planning future maintenance. It can also provide valuable information in the event of a warranty claim or if the valve needs to be replaced.

In conclusion, regular inspection, cleaning, lubrication, performance testing, and record-keeping are all essential aspects of soft shift directional valve maintenance. By following these steps, you can ensure that your valve continues to operate smoothly and efficiently, prolonging its lifespan and preventing costly repairs or replacements. Remember, the key to effective maintenance is consistency and attention to detail. By taking the time to care for your soft shift directional valve, you can ensure that it continues to perform at its best, supporting the overall performance and reliability of your hydraulic system.