Table of Contents

Understanding the Mechanism of Water Flow Control Valves

Water flow control valves are integral components in a wide range of systems, from household plumbing to industrial machinery. These devices regulate the flow of water through a system, ensuring that it operates at optimal efficiency. Understanding the mechanism of water flow control valves is crucial for anyone involved in their installation, maintenance, or use.

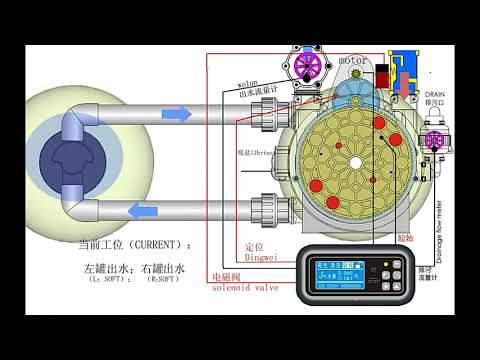

At its most basic, a water flow control valve is a device that adjusts the flow of water in a pipe. It does this by altering the size of the passage through which the water flows. The valve can either be fully open, fully closed, or somewhere in between. The position of the valve determines the amount of water that can pass through at any given time.

The operation of a water flow control valve is typically manual, but it can also be automated. Manual valves are operated by turning a handle or wheel, which moves a disc or plug inside the valve. This movement either opens or closes the passage for the water. On the other hand, automated valves use an actuator, a device that converts energy into motion. The actuator can be powered by electricity, hydraulic pressure, or pneumatic pressure. It receives a signal from a control system, which tells it how far to open or close the valve.

The design of a water flow control valve can vary greatly depending on its intended use. For instance, a globe valve, which is commonly used in residential and commercial plumbing, has a disc that moves up and down to control the flow of water. A butterfly valve, on the other hand, has a disc that rotates around a central axis. This type of valve is often used in large-scale industrial applications because it can handle high flow rates and pressures.

Despite their differences, all water flow control valves have one thing in common: they must be able to withstand the pressure of the water they control. This is why they are typically made of durable materials like brass, bronze, stainless steel, or plastic. The choice of material depends on the specific requirements of the system in which the valve will be used.

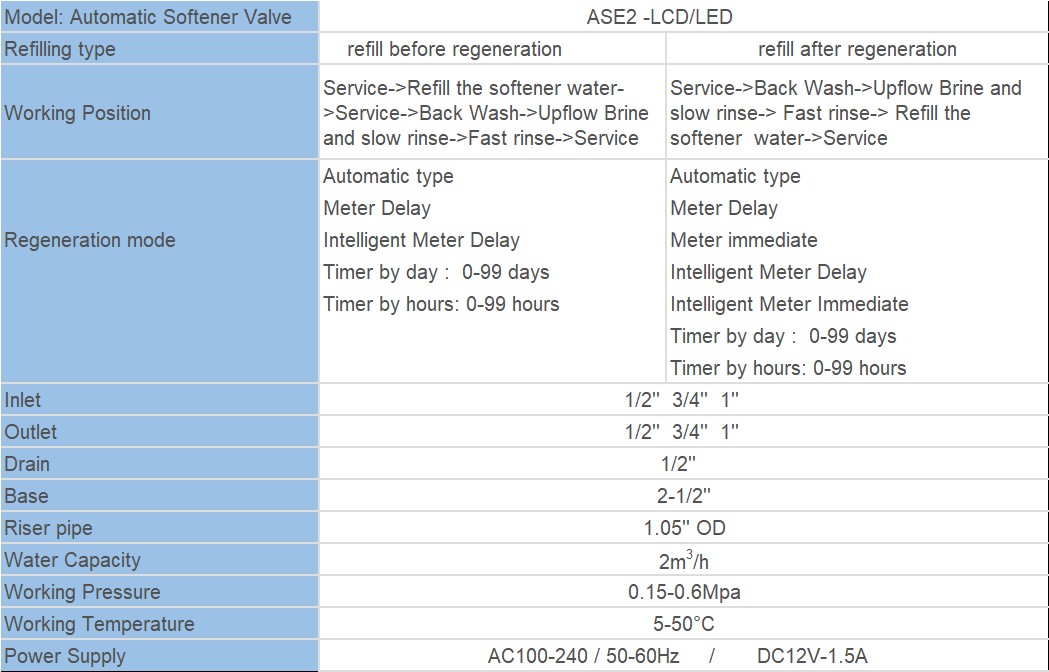

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| ASE2 | Advanced Function automatic softener valve | 2 | O | X | X | X |

| ASE4 | Advanced Function automatic softener valve | 4 | O | X | X | X |

| ASS2 | automatic softener valve | 2 | O | O | O | O |

In addition to regulating the flow of water, some control valves also have other functions. For example, pressure reducing valves not only control the flow of water but also reduce its pressure. This is particularly useful in systems where the water pressure is too high and could potentially damage the equipment or cause leaks.

Understanding the mechanism of water flow control valves is not just about knowing how they work. It’s also about understanding their role in a system and how they contribute to its overall performance and efficiency. For instance, a properly sized and correctly installed control valve can significantly reduce water waste in a plumbing system. Similarly, in an industrial setting, the right control valve can improve the efficiency of a process and reduce energy consumption.

In conclusion, water flow control valves are essential devices that regulate the flow of water in various systems. They operate by adjusting the size of the passage through which the water flows, and their design can vary depending on their intended use. Despite their differences, all control valves must be durable enough to withstand the pressure of the water they control. By understanding the mechanism of these valves, we can better appreciate their role in improving the efficiency and performance of the systems they are part of.

The Importance of Proper Maintenance for Water Flow Control Valves

Water flow control valves are integral components of many systems, playing a crucial role in regulating the flow and pressure of water in various applications such as irrigation, industrial processes, and domestic water supply. These valves, through their ability to control the rate of flow, ensure the efficient operation of these systems. However, the importance of proper maintenance for water flow control valves cannot be overstated.

The primary function of a water flow control valve is to regulate the flow of water in a system. This is achieved by adjusting the size of the valve opening, which in turn, controls the amount of water that can pass through at any given time. This regulation is crucial in preventing damage to the system caused by excessive pressure or flow rate. For instance, in an irrigation system, a properly functioning control valve can prevent overwatering or underwatering, which could potentially harm the crops.

However, like any other mechanical device, water flow control valves are subject to wear and tear. Over time, the valve components may degrade, leading to a decrease in performance and efficiency. This could result in a variety of issues, such as leaks, irregular water flow, and even system failure. Therefore, regular maintenance is essential to ensure the longevity and optimal performance of these valves.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 2850 | 1.9″(1.5″)O.D. | 1″NPTM | 3/8″&1/2″ | 4″-8UN | 72W | 1℃-43℃ |

Maintenance of water flow control valves typically involves regular inspections, cleaning, and replacement of worn-out parts. During inspections, it is important to check for signs of wear and tear, such as corrosion, leaks, or damage to the valve components. Any issues identified should be addressed promptly to prevent further damage. Cleaning the valve regularly can also help to remove any debris or buildup that may hinder its operation.

In some cases, parts of the valve may need to be replaced. This could include the valve seat, which can wear out over time due to constant contact with water, or the valve stem, which may become corroded. Replacing these parts when necessary can help to maintain the valve’s performance and extend its lifespan.

Moreover, proper maintenance of water flow control valves can also lead to cost savings. By ensuring that the valves are functioning optimally, water wastage can be minimized, leading to lower water bills. Additionally, regular maintenance can help to prevent major system failures, which could potentially result in costly repairs or replacements.

In conclusion, the importance of proper maintenance for water flow control valves cannot be overstated. These valves play a crucial role in regulating the flow and pressure of water in various systems, and their optimal performance is essential for the efficient operation of these systems. Regular inspections, cleaning, and replacement of worn-out parts can help to ensure the longevity and performance of these valves, leading to cost savings and preventing potential system failures. Therefore, it is essential for individuals and organizations to invest time and resources in the regular maintenance of their water flow control valves.